Home > News > Industry News > Multi-Tube Metal Needles: How They Boost Adhesive Throughput in High-Speed Applications

Multi-Tube Metal Needles: How They Boost Adhesive Throughput in High-Speed Applications

In today’s world of mass production and advanced manufacturing, efficiency is just as important as precision. Whether in electronics, automotive, or packaging industries, the ability to dispense adhesives accurately and quickly can determine overall productivity. One of the innovative solutions that has emerged to address this challenge is the multi-tube metal needle.

Unlike traditional single-tube dispensing needles, multi-tube designs allow adhesives to be dispensed simultaneously through multiple channels. This not only improves throughput but also ensures uniformity across multiple points of application. In this article, we’ll explore what multi-tube metal needles are, how they work, and why they’re becoming an indispensable tool for high-speed adhesive applications.

For detailed specifications, you can explore Contriu's multi-tube metal needle solutions here.

Why Adhesive Throughput Matters

Adhesives are used in countless industries:

Electronics: bonding components on circuit boards.

Automotive: sealing joints and attaching trims.

Packaging: assembling cartons and applying tamper-proof seals.

Medical devices: producing components that require sterile, accurate adhesive application.

In each of these settings, throughput—or the amount of adhesive applied in a given time—directly impacts efficiency. When hundreds or thousands of units need assembly daily, every second counts. Standard single-needle systems often become a bottleneck, as they can only dispense adhesive at one point at a time.

This is where multi-tube metal needles step in.

What Are Multi-Tube Metal Needles?

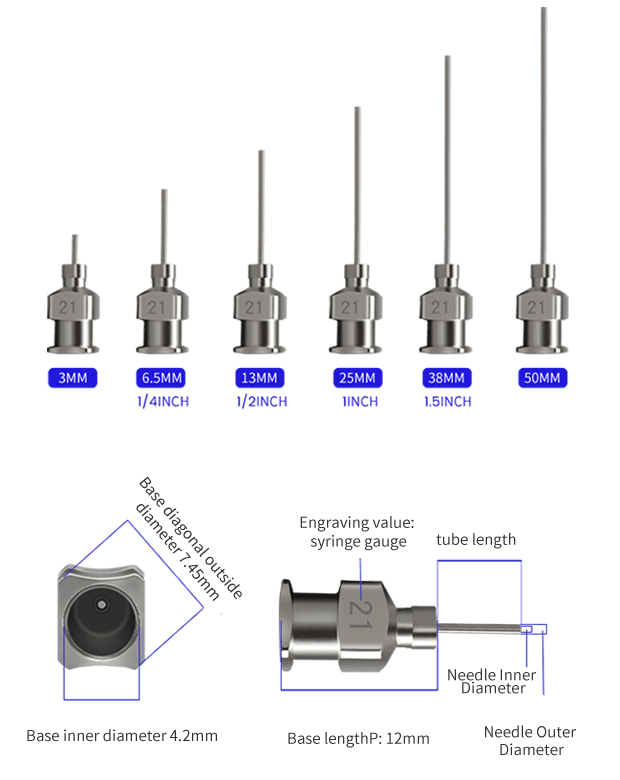

Multi-tube metal needles are dispensing tips engineered with two or more stainless steel channels, allowing adhesives or sealants to flow simultaneously from multiple outlets. Instead of applying adhesive one point at a time, operators can apply multiple points in a single pass.

Key Features Include:

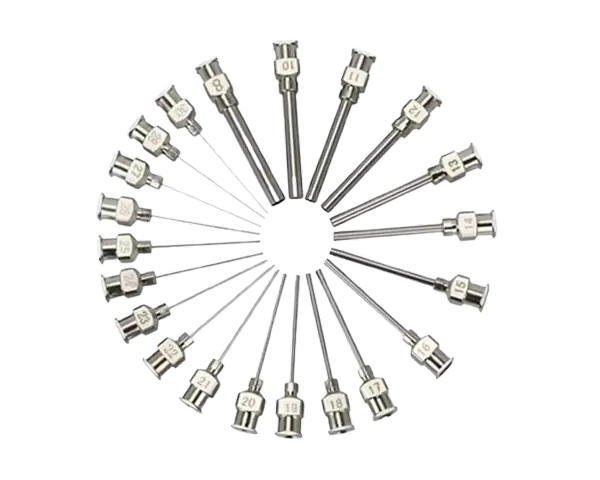

Multiple outlets (2, 3, or more tubes).

Uniform inner diameters for consistent adhesive flow.

Durable stainless steel construction resistant to chemicals and wear.

Compatibility with standard syringes, pneumatic dispensers, and automated dispensing systems.

This design significantly reduces cycle times while ensuring accuracy and repeatability.

Benefits of Multi-Tube Metal Needles in High-Speed Applications

1. Increased Productivity

By applying adhesives at multiple points simultaneously, manufacturers reduce the number of dispensing cycles. This is especially valuable in automated production lines where seconds saved per unit translate into hours saved over a week.

2. Consistent Adhesive Application

Multi-tube needles are engineered to ensure each tube dispenses adhesive at the same rate. This uniformity reduces errors like uneven bonding, weak joints, or excess adhesive waste.

3. Versatility in Design

Different industries require different adhesive patterns. Multi-tube needles can be customized in terms of:

Tube number (dual, triple, or custom).

Spacing between tubes.

Tube length and gauge to match viscosity and application needs.

4. Reduced Operator Fatigue

For manual applications, multi-tube designs reduce repetitive movements, making workflows more ergonomic and efficient.

5. Integration with Automation

Multi-tube metal needles integrate seamlessly with robotic dispensing systems, making them ideal for high-speed, automated manufacturing environments.

When to Use Multi-Tube Metal Needles

Mass Production Lines: Electronics assembly where hundreds of solder points need adhesives.

Symmetrical Adhesive Application: Automotive sealing tasks requiring balanced distribution.

Multi-Point Bonding: Packaging where multiple glue lines are required per unit.

Medical Devices: Precision bonding of small, multiple components.

For instance, in smartphone manufacturing, multi-tube needles can simultaneously bond multiple small components on a circuit board, cutting down production time without compromising accuracy.

Challenges and Solutions

Even with their advantages, multi-tube needles come with challenges that can be mitigated with best practices.

Clogging

Multiple tubes mean multiple chances for clogging. To prevent this:

Use the right gauge for adhesive viscosity.

Implement immediate cleaning protocols after use.

Calibration

Ensuring equal flow across all tubes requires precise calibration. Manufacturers like Contriu design their multi-tube needles with uniform inner diameters to maintain balance.

Cost

Multi-tube needles are often more expensive than single-tube options. However, the cost is offset by higher throughput and reduced waste.

Best Practices for Maximizing Performance

Match Needle Size to Adhesive Viscosity

Thicker adhesives require larger gauges to prevent clogging.Test Flow Rates Before Production

Conduct small-scale trials to ensure adhesive is dispensing evenly across all tubes.Maintain Regular Cleaning Schedules

Prevent buildup by flushing with compatible solvents after use.Store Needles Properly

Keep them capped and stored in dry environments to prevent contamination or damage.Train Operators Thoroughly

Proper training ensures optimal use and maintenance, extending the lifespan of the needles.

Industry Examples of High-Speed Use

Electronics

In PCB assembly, adhesives are often applied in multiple points across the board. Multi-tube needles make this faster while maintaining precision.

Automotive

Sealants and adhesives used in interior assembly can be applied symmetrically using dual or triple-tube needles.

Packaging

Carton and container sealing benefit from multi-line adhesive application, reducing machine cycles.

Medical Devices

Multi-component bonding in diagnostic kits or disposable medical devices requires multiple adhesive dots placed with accuracy—perfect for multi-tube needles.

The Contriu Advantage

Contriu’s multi-tube metal needles are engineered with precision and reliability in mind. They are:

Made from stainless steel for maximum durability.

Available in multiple sizes and tube configurations to suit different industries.

Compatible with most dispensing systems, including manual, pneumatic, and automated setups.

For businesses looking to increase throughput without sacrificing quality, Contriu offers solutions tailored to high-speed environments. Learn more about their products here.

External Resources

For further insights into adhesive dispensing technology, check out:

Adhesives.org – for adhesive application trends and technology updates.

Nordson Dispensing Systems – industry leader in automated dispensing equipment.

Conclusion

As industries move toward faster and more automated production, the demand for efficient adhesive dispensing solutions grows. Multi-tube metal needles are a practical innovation, offering improved throughput, consistent results, and adaptability across various applications.

By choosing high-quality options like Contriu’s stainless steel multi-tube needles, manufacturers can achieve the perfect balance between speed and precision—critical factors in today’s competitive markets.