Home > News > Industry News > Advanced Brush Needle Solutions for High-Efficiency Industrial Coating

Advanced Brush Needle Solutions for High-Efficiency Industrial Coating

In modern manufacturing, surface treatment is no longer a peripheral process—it is a decisive factor in product performance, durability, and visual quality. Whether applying lubricating oil to precision components or coating functional layers of ink, paint, or specialty materials, manufacturers increasingly rely on tools that offer consistency, control, and safety. Among these tools, the Brush Needle plays a critical but often underestimated role. When engineered correctly, it becomes a productivity amplifier; when poorly designed, it introduces contamination, uneven coatings, and costly rework.

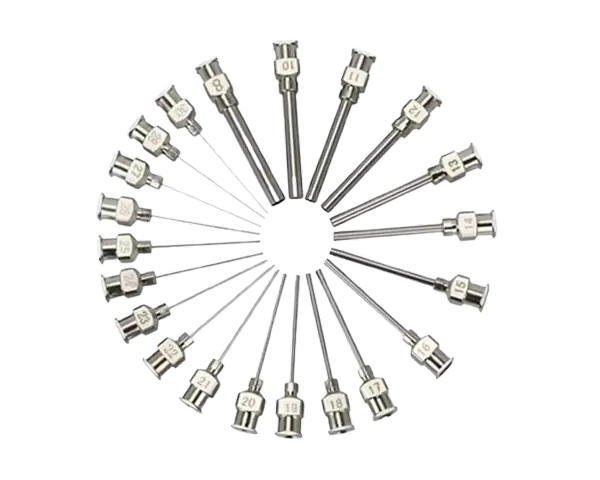

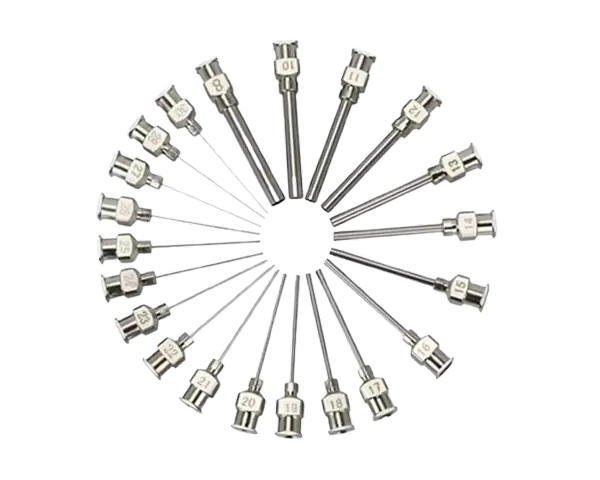

What Is a Brush Needle and Why It Is Technically Distinct

A brush needle is a precision applicator designed for controlled distribution of liquids and semi-liquids onto surfaces. Unlike traditional brushes or rollers, brush needles are optimized for:

Accurate material transfer

Minimal waste and dripping

Uniform coating thickness

Compatibility with automated or semi-automated systems

The effectiveness of a brush needle is determined less by its appearance and more by its material science, structural design, and interaction with coating media.

High-End Nylon Material: The Core of Performance

Contriu’s brush needles are manufactured using high-end industrial nylon, a material selected for its balanced mechanical and chemical properties.

Key Material Advantages

Excellent toughness: Maintains structural integrity under repeated use and mechanical stress

No hair loss: Eliminates fiber shedding that could contaminate coatings or interfere with downstream processes

Anti-static performance: Reduces dust attraction, particularly important in ink, paint, and precision coating environments

This material stability ensures predictable behavior during application, even when working with volatile or viscosity-sensitive substances.

Burr-Free Design for Coating Consistency

One of the most critical but overlooked aspects of brush needle engineering is the absence of burrs or sharp edges. Any microscopic irregularity can disrupt liquid flow, trap coating material, or damage sensitive product surfaces.

Contriu’s brush needles adopt a no-burr design, delivering several practical benefits:

Consistent glue, oil, or coating distribution

Smooth liquid release without accumulation points

Reduced risk of streaking or uneven layers

This design precision directly translates into higher first-pass yield and less post-processing correction.

Soft Contact, Maximum Protection

In many industries—electronics, automotive components, packaging, and decorative coatings—surface integrity is non-negotiable. The soft nylon hair structure of the brush needle ensures gentle contact with products while maintaining precise application control.

This soft-touch interaction means:

No surface scratching or abrasion

Safe application on polished, coated, or sensitive substrates

Improved reliability in high-value manufacturing environments

The result is a safer, more dependable coating process that protects both the product and the production schedule.

Broad Application Compatibility Across Industries

A major strength of modern brush needles is their versatility. High-quality brush needles from Contriu are suitable for a wide range of coating and lubrication tasks, including:

Lubricating oil application for mechanical parts

Coating and covering materials in industrial finishing

Ink application in printing and marking processes

Paint and protective layer distribution in manufacturing and assembly

This adaptability allows manufacturers to standardize tools across production lines, reducing inventory complexity and training costs.

Productivity Gains Through Process Optimization

The true value of an advanced brush needle lies in its impact on surface coating efficiency and productivity. By ensuring consistent application and reducing defects, manufacturers can achieve:

Faster processing times

Lower material consumption

Reduced rework and scrap rates

Improved automation compatibility

In high-volume production environments, even small efficiency gains can translate into significant cost savings over time.

Why Global Manufacturers Choose Contriu

Contriu positions itself not merely as a component supplier, but as a solution-oriented manufacturer focused on real industrial challenges. By combining material expertise, precision manufacturing, and application-driven design, Contriu’s brush needles meet the demands of modern surface treatment processes.

Manufacturers working with Contriu benefit from:

Stable, industrial-grade product quality

Consistent performance across batches

Tools designed for both manual and automated use

Long-term reliability in demanding production environments

This approach makes Contriu a trusted partner for companies seeking to improve coating performance without compromising safety or efficiency.

Conclusion

The brush needle may appear to be a minor component, but in practice it plays a strategic role in surface treatment quality and efficiency. From burr-free construction to anti-static, no-shedding nylon fibers, every design detail contributes to consistent, safe, and high-performance coating processes.

With its focus on advanced materials and application-driven engineering, Contriu demonstrates how precision brush needle solutions can deliver measurable value across industries—proving that sometimes, productivity improvements begin with the smallest tools.