Home > News > Industry News > Elevating Precision Dispensing: The Role of Plastic Steel Needles in Various Industries

Elevating Precision Dispensing: The Role of Plastic Steel Needles in Various Industries

In high-precision manufacturing environments, the smallest component often determines the success or failure of an entire process. From micro-electronics and medical devices to automotive assembly and industrial adhesives, precision dispensing requires absolute control over flow accuracy, material stability, and repeatability.

At the center of this demand lies a seemingly simple yet highly engineered component: the Plastic Steel Needle. Far from a basic consumable, modern plastic steel needles are the result of advanced material science, precision machining, and application-specific design. Companies like Contriu have elevated this component into a performance-critical tool for multi-industry dispensing solutions.

What Is a Plastic Steel Needle?

A Plastic Steel Needle is a precision dispensing needle assembly designed for controlled fluid output in automated or manual dispensing systems. Unlike conventional needles, plastic steel needles combine metallic structural strength with optimized surface treatments to enhance durability, corrosion resistance, and dispensing accuracy.

These needles are commonly used for:

Adhesives and sealants

Lubricants and oils

Chemicals and solvents

Resins, silicones, and epoxies

Medical and laboratory fluids

Core Structural Design: Engineered for Stability and Accuracy

1. Brass Nickel-Plated Needle Holder

The needle holder is manufactured from high-strength brass, then treated with nickel plating. This combination delivers:

Excellent corrosion resistance, even in chemically aggressive environments

Enhanced wear resistance for long-term repetitive use

Stable threading and dimensional consistency

Nickel plating also reduces surface oxidation, ensuring consistent performance across extended production cycles.

2. 304 Stainless Steel Needle Tube

The needle tube is produced using 304 stainless steel, a material widely recognized for its:

High rigidity and mechanical strength

Excellent chemical compatibility

Resistance to deformation under pressure

This rigidity ensures that the needle maintains its internal diameter and alignment, which is essential for stable flow rate control and repeatable dispensing accuracy.

3. Bayonet Base for Secure Connection

A precision-machined bayonet base ensures a solid and vibration-resistant connection between the needle and dispensing equipment. Compared to conventional threaded-only designs, the bayonet structure:

Improves installation efficiency

Minimizes loosening during operation

Enhances system reliability in automated production lines

Precision Machining: No Burrs, No Compromise

One of the most critical performance factors of a plastic steel needle is internal and external surface finish. Poor machining can lead to burrs, micro-obstructions, and turbulent flow—resulting in inconsistent dispensing or material stringing.

Contriu employs high-precision machining processes that ensure:

Burr-free needle tips

Smooth internal flow channels

Clean, uniform outlets

This level of precision directly protects multi-industry dispensing accuracy, ensuring smooth, controlled, and repeatable material output.

Standard Specifications and Customization Capability

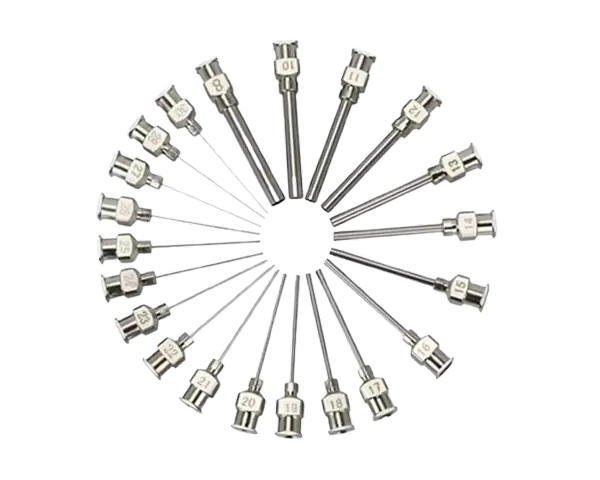

To meet diverse industrial requirements, Plastic Steel Needles are available in multiple conventional sizes:

1/4 inch (6.5 mm)

1/2 inch (13 mm)

1 inch (25 mm)

1.5 inch (38 mm)

Beyond standard lengths, any length customization is supported, allowing manufacturers to adapt the needle to:

Confined installation spaces

Deep cavity dispensing

Specialized automation equipment

This flexibility makes plastic steel needles suitable for both standardized production lines and highly customized industrial systems.

Multi-Industry Applications: Where Plastic Steel Needles Excel

Electronics Manufacturing

Used for precise application of adhesives, underfills, and thermal interface materials without overflow or contamination.

Medical and Laboratory Equipment

Ensures controlled dispensing of fluids where hygiene, accuracy, and material compatibility are essential.

Automotive and Industrial Assembly

Supports reliable application of sealants, lubricants, and bonding agents under demanding conditions.

Packaging and Consumer Goods

Improves production efficiency by delivering consistent adhesive patterns and reducing material waste.

Why Choose Contriu Plastic Steel Needles?

Contriu focuses on engineering-driven manufacturing, not just component production. Each plastic steel needle is designed with real-world dispensing challenges in mind:

Stable material flow

Long service life

High compatibility with automated systems

Consistent performance across industries

By combining material expertise, precision machining, and customization capability, Contriu provides dispensing solutions that go beyond basic functionality.

Conclusion

In precision dispensing, performance is defined by control, consistency, and reliability. The Plastic Steel Needle exemplifies how advanced materials and thoughtful engineering can transform a small component into a critical production asset.

For manufacturers seeking higher accuracy, reduced downtime, and improved dispensing quality, plastic steel needles from Contriu represent a smart, future-ready choice.