Home > News > Industry News > Precision at High Heat: Why PUR Needles Define Accuracy in Modern Hot-Melt Dispensing

Precision at High Heat: Why PUR Needles Define Accuracy in Modern Hot-Melt Dispensing

In industries where bonding performance directly affects product durability, appearance, and lifecycle value, Polyurethane Reactive hot-melt adhesives have become a preferred solution. PUR adhesives are known for their exceptional strength, moisture resistance, and long-term stability. However, these advantages can only be realized when the adhesive is applied with absolute control.

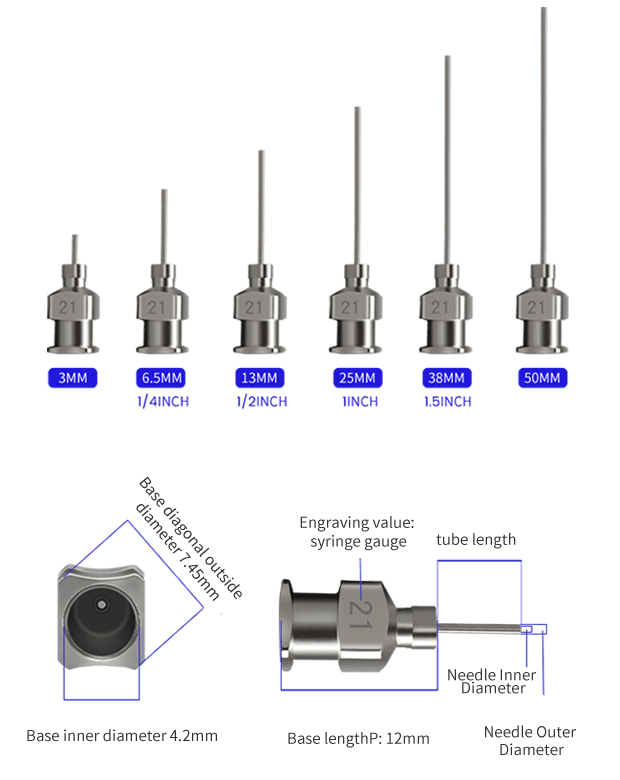

This is where the PUR Needle becomes a decisive factor. Often underestimated, the needle governs adhesive flow behavior at high temperature and determines whether PUR material is delivered cleanly, consistently, and repeatably. Contriu develops precision dispensing components such as the PUR High-Temperature Hot-Melt Adhesive Precision Double-Thread Needle to meet the demanding realities of modern production environments.

The Functional Role of a PUR Needle in Hot-Melt Systems

A PUR Needle is a precision-machined component installed inside hot-melt applicators or dispensing valves. Its primary function is to regulate adhesive flow during opening and closing cycles while maintaining reliable sealing at elevated temperatures.

Unlike standard hot-melt systems, PUR adhesives introduce unique challenges. The material remains molten during application but reacts chemically with ambient moisture after dispensing. This requires the needle to perform flawlessly under continuous heat exposure while resisting adhesive buildup and curing residue.

A properly engineered PUR needle ensures stable flow, clean cutoff, and minimal stringing, all of which are essential for high-quality bonding results.

Why High-Temperature Performance Is Non-Negotiable

PUR dispensing typically occurs at temperatures significantly higher than conventional EVA hot-melt systems. Under these conditions, thermal expansion, material fatigue, and surface degradation become real risks.

A PUR High-Temperature Hot-Melt Adhesive Precision Double-Thread Needle is specifically designed to maintain dimensional stability and sealing integrity despite prolonged heat exposure. Contriu selects materials and machining tolerances that support long-term operation without deformation or loss of control.

High-temperature resistance directly impacts production uptime by reducing the risk of clogging, leakage, and premature component failure.

Engineering Value of the Precision Double-Thread Design

One of the most critical differentiators in advanced PUR needles is the double-thread structure. This design is not cosmetic; it directly influences flow stability and pressure distribution inside the dispensing system.

The precision double-thread configuration enables smoother adhesive guidance, reduces internal turbulence, and enhances sealing behavior during shut-off. Compared to single-thread designs, it delivers more consistent bead formation and improved repeatability across long production runs.

Contriu’s precision machining capabilities ensure that each thread profile is manufactured with tight tolerances, allowing predictable performance even in high-speed, high-volume dispensing operations.

Surface Finish and Machining Accuracy Matter More Than Expected

In PUR applications, microscopic surface imperfections can become major operational problems. Adhesive residue tends to accumulate on rough or inconsistent surfaces, increasing the risk of blockage and irregular flow.

A high-quality PUR needle requires optimized surface roughness, precise concentricity, and accurate alignment between mating components. Contriu applies advanced CNC machining and inspection processes to ensure each needle meets stringent dimensional and surface quality standards.

This attention to detail directly translates into cleaner dispensing, reduced maintenance frequency, and more stable adhesive output.

Application Scenarios That Demand Precision PUR Needles

In furniture and woodworking industries, PUR adhesives are widely used for edge banding and panel bonding, where clean glue lines and long-term durability are essential. A stable PUR needle ensures consistent adhesive delivery without overflow or stringing.

In automotive interiors and transportation components, PUR bonding supports lightweight structures and vibration resistance. Precision dispensing needles help maintain uniform adhesive application under high-volume production conditions.

Electronics and industrial assembly applications also rely on controlled PUR dispensing in confined spaces, where accuracy protects sensitive components while ensuring strong bonds.

Process Efficiency Gains Through the Right PUR Needle

Selecting the correct PUR needle is not only a technical decision but also a process optimization strategy. A well-designed PUR High-Temperature Hot-Melt Adhesive Precision Double-Thread Needle contributes to reduced adhesive consumption, fewer rejects, and improved consistency.

By minimizing clogging and extending service intervals, precision needles help manufacturers stabilize production schedules and lower total operating costs. These benefits compound over time, especially in continuous or automated production lines.

Quality Control and System Compatibility

High-performance PUR needles must integrate seamlessly with a variety of dispensing systems and adhesive formulations. Dimensional consistency, material traceability, and thread accuracy are essential to ensure compatibility and repeatable performance.

Contriu maintains strict quality control procedures throughout production, from raw material selection to final inspection. This ensures that each PUR needle delivered supports reliable system integration and long-term operational stability.

Why Contriu Is a Reliable Partner for PUR Needle Solutions

Contriu focuses on precision components engineered for demanding industrial dispensing environments. By combining material science expertise, high-accuracy machining, and application-driven design, the company delivers PUR needle solutions that support consistent adhesive performance under high thermal and mechanical stress.

Rather than offering generic components, Contriu develops dispensing solutions aligned with real production challenges, helping manufacturers achieve better control, higher efficiency, and improved product quality.

In PUR hot-melt adhesive systems, precision is never optional. The PUR Needle serves as the final control point between adhesive technology and finished product quality. When engineered correctly, it transforms high-temperature adhesive potential into reliable, repeatable performance.

With its PUR High-Temperature Hot-Melt Adhesive Precision Double-Thread Needle, Contriu provides manufacturers with a critical component that enhances dispensing accuracy, reduces downtime, and supports long-term production stability.