Home > News > Industry News > Engineered for Precision: Metal Sleeves That Transform Dispensing Efficiency

Engineered for Precision: Metal Sleeves That Transform Dispensing Efficiency

In today’s manufacturing and assembly environments, adhesive dispensing has become a mission-critical step across electronics, construction, automotive, packaging, and general industrial production. Whether used for silicone, glass glue, structural adhesives, or high-viscosity sealants, a stable and contamination-free dispensing process directly affects product quality, line efficiency, and long-term reliability.

A well-engineered Metal Sleeve is at the center of this process. Far more than a simple mechanical container, a metal sleeve acts as the core pressure-bearing and sealing component that enables consistent, controlled, and waste-free dispensing. For companies looking to enhance the stability and output of their adhesive workflows, a premium metal sleeve is an indispensable investment.

1. What Is a Metal Sleeve and Why It Matters in Adhesive Dispensing

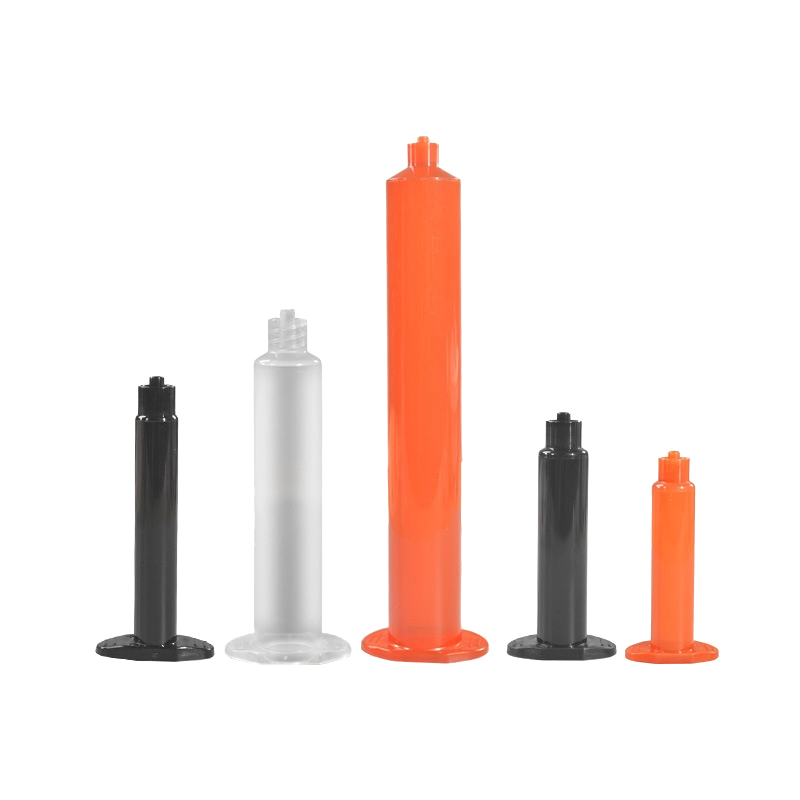

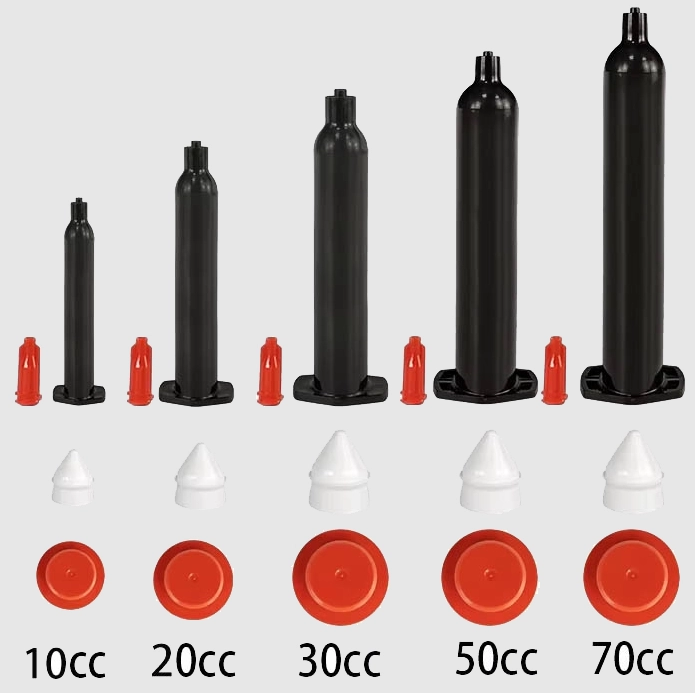

A metal sleeve is a pressure-resistant, reusable barrel designed to hold tubular adhesive packaging. It replaces the need for traditional plastic cartridges and improves dispensing performance across all major adhesive types, including:

Red glue

Silicone

Glass glue

Sealants

High-viscosity adhesives

Toothpaste-type aluminum tubes for precision dispensing

Unlike disposable cartridges, a metal sleeve:

Provides higher structural strength

Offers better pressure resistance

Ensures consistent adhesive extrusion

Reduces deformation during air-pressure dispensing

Enhances production efficiency

This combination of mechanical stability and operational control makes metal sleeves essential for industries that require stable, batch-consistent adhesive application.

2. Advanced Material Engineering: Why Aluminum Alloy Matters

The performance of a metal sleeve is largely determined by its raw material and surface finishing. Contriu uses high-grade aluminum alloy, processed through:

◆ Anodizing Treatment

Improves corrosion resistance, surface hardness, and wear resistance.

Protects the sleeve from chemical attack caused by adhesives, solvents, and cleaning agents.

◆ Blackening Treatment

Provides an anti-rust finish, reduces reflective glare for machine vision environments, and enhances aesthetics.

◆ Lightweight Structure

Compared to steel, anodized aluminum sleeves:

Reduce operator fatigue during manual operation

Lower inertia during automated dispensing

Improve safety and ergonomics

This makes the sleeves particularly beneficial for high-frequency production lines where quick changeovers are required.

3. Manual Dispensing vs. Automated Systems: One Sleeve for All Modes

A major advantage of Contriu’s metal sleeve design is its compatibility with multiple dispensing methods.

3.1 Manual Operation

The ergonomic design ensures:

Smooth, controlled extrusion

Lower force requirement

Reduced viscosity sensitivity

No deformation during high-pressure manual pumping

This helps operators maintain consistent dispensing quality even during long shifts.

3.2 Automated Dispensing Machine Integration

The sleeve can be directly installed into:

Pneumatic dispensing machines

Glue dispensing robots

Precision dosing systems

Semi-automatic and fully automatic production lines

Through controlled air pressure, the sleeve ensures:

Consistent flow rate

Stable bead formation

Reduced adhesive wastage

Precise start/stop dispensing

This supports modern industrial requirements where precision, speed, and repeatability are non-negotiable.

4. Full-Container Feeding: High Volume and High Stability

For large-scale manufacturing tasks, the entire adhesive tube is placed inside the metal sleeve. Air pressure is then used to punch out the contents, offering:

Higher extrusion force

Reduced operator involvement

Greater production stability

Better control during high-viscosity glue dispensing

This method is especially useful in construction sealants, electronics potting, and assembly gluing where adhesives may require significant pressure to achieve proper flow.

5. Toothpaste-Type Metal Sleeves: Precision Compatibility

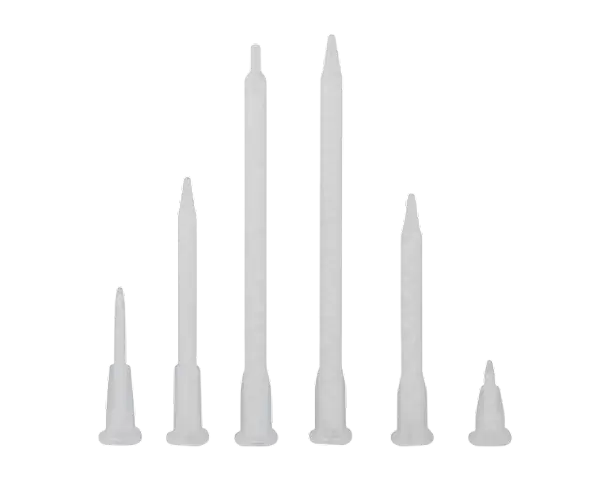

Contriu also provides toothpaste-type metal sleeves, which are designed to work with a wide variety of dispensing needles, including:

Precision micro-needles

Conical tapered needles

Stainless steel blunt needles

Flat-tip and angled-tip nozzles

This compatibility makes the sleeve a versatile tool for electronics assembly, PCB repair, micro-bonding, and fine-line sealing applications.

6. How Metal Sleeves Improve Production Capacity

Upgrading to a high-grade metal sleeve has clear operational and economic benefits:

◆ Higher Dispensing Accuracy

Preventing tube expansion or bursting under pressure leads to stable adhesive output.

◆ Reduced Material Waste

The rigid structure ensures complete extrusion of adhesive from the packaging.

◆ Enhanced Safety and Cleanliness

No unexpected adhesive leakage or uncontrolled flow.

◆ Extended Equipment Service Life

Stable sleeve geometry protects needles, nozzles, and dispensing components.

◆ Improved Operator Efficiency

Lightweight aluminum reduces physical strain and increases handling speed.

These advantages translate into higher throughput, lower costs, and more predictable product quality.

7. Why Manufacturers Choose Contriu Metal Sleeves

Contriu’s expertise lies in the integration of:

Advanced materials engineering

Precision machining

Industrial-grade surface finishing

Compatibility with global dispensing machinery

Strict quality control

Manufacturers rely on Contriu because:

Every sleeve is built for long-term reliability

The designs support both high-volume production lines and precision assembly

The company offers consistent product quality across batches

The sleeves perform well even under continuous high-pressure cycles

This makes Contriu a trusted partner for companies looking to scale their adhesive dispensing operations with confidence.

Conclusion

A Metal Sleeve is more than a simple container—it is a precision-engineered solution that ensures stability, efficiency, and accuracy in adhesive dispensing. With aluminum alloy construction, anodizing and blackening treatments, and full compatibility with manual or automated systems, a high-quality sleeve can significantly elevate production performance.

Contriu delivers metal sleeves that combine strength, lightweight usability, chemical resistance, and multi-needle compatibility, making them an essential component in modern industrial adhesive workflows.

For companies committed to improving their dispensing quality and output, upgrading to a Contriu metal sleeve is a highly strategic investment.