Optimizing Industrial Flow with High-Efficiency Static Mixers

In modern industrial processes, achieving uniform fluid mixing is critical for product quality, chemical reactions, and operational efficiency. From chemical processing to water treatment and food production, the ability to combine liquids, gases, or powders without moving parts has revolutionized efficiency and safety.

The MA Static Mixer is at the forefront of this technology, providing high-efficiency mixing solutions that eliminate the need for mechanical agitation while ensuring consistent product homogeneity. Contriu, a leader in industrial mixing solutions, has engineered MA static mixers to deliver exceptional performance across a range of industries.

What is an MA Static Mixer

A static mixer is a device inserted into a pipeline that mixes fluids as they flow through, using fixed internal elements rather than moving parts. The MA static mixer, in particular, is designed for high-efficiency turbulent and laminar mixing, suitable for liquids, gases, and multiphase flows.

Key characteristics include:

No moving parts, reducing maintenance costs

Compact design, ideal for pipeline integration

High mixing efficiency, even under variable flow rates

Material versatility, including stainless steel, PVC, and specialty alloys

Scalability, adaptable to different pipe diameters and flow conditions

Contriu’s MA mixers combine precise engineering and durable materials to ensure long-term reliability.

Engineering Principles Behind MA Static Mixers

1. Helical Mixing Elements

The core of the MA static mixer is a series of helical or plate-type elements that split, rotate, and recombine fluid streams. This design ensures:

Reduced laminar flow separation

Enhanced turbulence without external energy input

Consistent homogenization of multi-component fluids

Contriu engineers optimize the pitch, length, and number of elements based on fluid properties to maximize efficiency.

2. Laminar and Turbulent Flow Optimization

MA static mixers are designed to operate effectively under both laminar and turbulent flow regimes:

Laminar flows benefit from controlled splitting and folding of fluid layers

Turbulent flows achieve rapid homogenization while maintaining low pressure drop

This makes MA mixers suitable for precise chemical dosing, temperature control in process streams, and viscous fluid blending.

3. Reduced Maintenance and Operational Costs

Unlike mechanical mixers, MA static mixers have no moving components:

No bearings or seals to wear out

Minimal risk of mechanical failure

Lower energy consumption, since mixing relies entirely on fluid motion

Contriu’s MA static mixers are engineered to withstand harsh chemical environments, minimizing downtime and long-term operating costs.

4. Scalability and Customization

Industrial applications vary significantly in flow rates, viscosities, and chemical properties. Contriu offers:

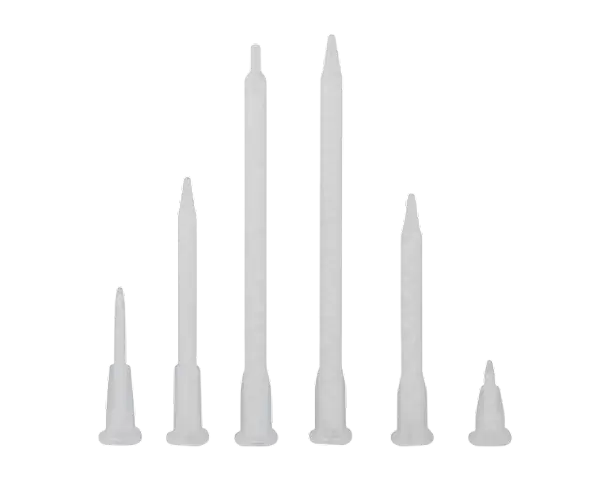

Custom pipe diameters from small lab-scale systems to industrial pipelines

Selection of corrosion-resistant materials for aggressive chemicals

Configurable mixing element layouts to optimize shear and residence time

This ensures each installation achieves optimal mixing efficiency and process consistency.

Industrial Applications of MA Static Mixers

1. Chemical Processing

In chemical reactors and continuous production lines, uniform mixing is critical:

Reduces reaction time variability

Prevents hotspots in exothermic reactions

Improves yield and product consistency

MA static mixers from Contriu maintain precise homogeneity without requiring moving mixers, reducing contamination risk.

2. Water and Wastewater Treatment

Static mixers are widely used for:

Coagulation and flocculation dosing

pH neutralization

Disinfection chemical blending

The MA static mixer ensures that treatment chemicals are evenly distributed, enhancing water quality and process efficiency.

3. Food and Beverage Industry

Viscous syrups, dairy products, and beverage blends require controlled mixing. MA static mixers offer:

Gentle mixing to avoid foaming

Consistent flavor and texture

Compliance with hygiene and food safety standards

Contriu’s mixers are fabricated with FDA-compliant materials and smooth internal finishes to maintain sanitation.

4. Polymer and Adhesive Production

Uniform blending of monomers, resins, and catalysts is essential in polymer manufacturing. Static mixers:

Reduce reaction variability

Maintain product consistency

Minimize material waste

Contriu engineers configure MA mixers for high-viscosity fluids, ensuring homogeneous mixing across production volumes.

Key Benefits of Contriu’s MA Static Mixers

Energy Efficiency – No additional power input needed beyond fluid flow.

Low Pressure Drop – Optimized element design minimizes pipeline resistance.

Chemical Compatibility – Constructed from high-quality alloys resistant to corrosion.

Minimal Maintenance – Long-term reliability with no moving parts.

Flexibility – Adaptable to a variety of flow rates, viscosities, and pipe sizes.

These benefits make MA static mixers an indispensable component in modern industrial systems.

Conclusion: Precision, Reliability, and Efficiency

The MA Static Mixer is a versatile solution for industries seeking precise, cost-effective, and low-maintenance mixing. By integrating advanced engineering and durable materials, Contriu delivers mixers that optimize fluid dynamics, improve process consistency, and reduce operational costs.

For chemical, water treatment, food, and polymer industries, MA static mixers offer a reliable way to enhance product quality and operational efficiency without the complexity of mechanical mixing.