From Brass to Bonding: The Performance Logic of One-piece PUR Needles

In modern adhesive application systems, precision is not optional—it is a fundamental requirement. Whether used in packaging, woodworking, automotive interiors, or industrial assembly, polyurethane reactive (PUR) hot melt adhesives demand accurate flow control, thermal stability, and material compatibility. At the center of this precision lies a small yet critical component: the One-piece PUR needle.

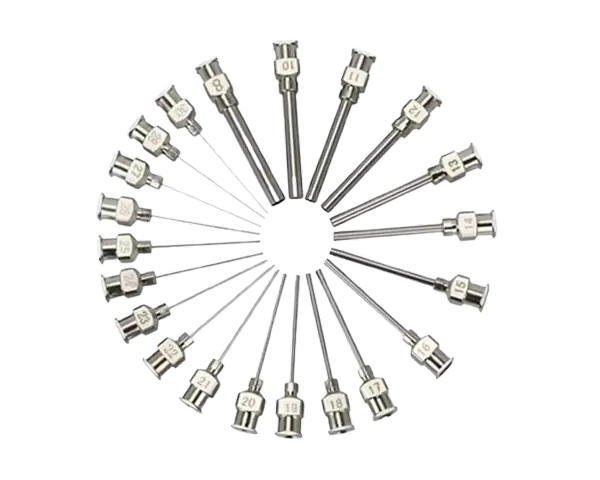

The Role of the One-piece PUR Needle in Adhesive Dispensing Systems

A One-piece PUR needle is a core control element in PUR hot melt dispensing equipment. Its primary function is to regulate adhesive flow with high accuracy while operating under elevated temperatures and chemically reactive conditions.

Unlike multi-component or assembled needle structures, a one-piece design eliminates internal junctions and weak points, resulting in:

More consistent adhesive flow

Reduced leakage risk

Higher mechanical integrity

Longer service life

This makes it particularly suitable for precision bonding applications where stability and repeatability are essential.

Integrated Machining Design: Why One-piece Construction Matters

The defining feature of a One-piece PUR needle is its integrated machining design. Manufactured as a single, continuous component, this structure offers significant advantages over segmented or welded alternatives.

Engineering Benefits of One-piece Construction:

No internal seams or joints that could trap adhesive

Improved dimensional consistency along the needle length

Enhanced resistance to thermal expansion stress

Simplified cleaning and maintenance

For high-temperature PUR systems, where adhesive viscosity and reactivity can fluctuate, this structural integrity directly translates into more reliable dispensing performance.

Premium Brass Material for Demanding Conditions

Material selection is critical for components exposed to hot melt PUR adhesives. The One-piece PUR needle is crafted from premium brass, chosen for its balanced mechanical and chemical properties.

Key Material Advantages:

Excellent corrosion and rust resistance

Strong thermal conductivity for stable temperature control

High-temperature tolerance suitable for PUR hot melt processes

Good machinability for precise dimensional control

Brass ensures that the needle maintains structural stability and surface quality even during prolonged high-temperature operation.

High-Temperature Performance and Adhesive Compatibility

PUR hot melt adhesives typically operate at elevated temperatures and undergo chemical reactions during curing. Components in contact with PUR must withstand:

Continuous thermal exposure

Chemical reactivity of uncured PUR

Repeated heating and cooling cycles

The One-piece PUR needle’s brass construction and seamless design allow it to maintain consistent performance without deformation, corrosion, or flow inconsistency, ensuring precise dispensing throughout the production cycle.

Precision Dispensing for Process Consistency

Accurate adhesive application is critical to product quality and cost control. A well-engineered One-piece PUR needle enables:

Stable adhesive output

Clean cut-off without stringing

Uniform bonding lines

Reduced adhesive waste

These benefits are especially important in automated production lines, where even minor dispensing inconsistencies can lead to defects or downtime.

Application Scenarios Across Industries

Due to its reliability and precision, the One-piece PUR needle is widely used in multiple industries:

Packaging Industry

Ensures clean, consistent bonding for cartons, boxes, and specialty packaging.

Woodworking and Furniture

Supports strong, durable joints for panels, edges, and laminated surfaces.

Automotive and Transportation

Used in interior trim, insulation, and component bonding requiring heat resistance.

Industrial Assembly

Provides precise adhesive control for electronics housings, filters, and composite parts.

Each application benefits from the needle’s resistance to corrosion, heat, and adhesive buildup.

Manufacturing Quality and Process Control

Professional One-piece PUR needle production requires strict control over:

Material purity

Machining accuracy

Surface finish quality

Dimensional tolerances

Reputable manufacturers implement thorough inspection and testing procedures to ensure consistent performance in real-world applications.

Contriu emphasizes precision machining and process stability, ensuring that every One-piece PUR needle meets functional and durability expectations for industrial use.

Why Choose Contriu for One-piece PUR Needles

Contriu is a specialized supplier of precision components for adhesive dispensing systems. With a focus on reliability and application performance, Contriu offers:

Integrated one-piece machining expertise

High-quality brass material selection

Stable production and batch consistency

Compatibility with a wide range of PUR dispensing equipment

By aligning material science with practical application requirements, Contriu supports manufacturers in achieving efficient, high-quality bonding results.

Conclusion

The One-piece PUR needle is a small but indispensable component in high-performance hot melt adhesive systems. Its integrated design, premium brass construction, and high-temperature resistance make it a superior choice for precise, reliable PUR adhesive dispensing.

For manufacturers seeking consistency, durability, and process control, partnering with an experienced supplier like Contriu ensures that adhesive application systems perform at their best—cycle after cycle.