Home > News > Industry News > Optimizing Glue Applications: The Role of MS Static Mixers in Industry

Optimizing Glue Applications: The Role of MS Static Mixers in Industry

In industries where two-component materials such as adhesives, resins, sealants, and reactive compounds are widely used, mixing accuracy directly determines product performance. Poor mixing can lead to incomplete curing, weak bonding strength, material waste, and unstable production quality.

The MS Static Mixer has become a core component in modern dispensing and gluing systems due to its simple structure, consistent mixing performance, and high production reliability. As industrial automation continues to evolve, manufacturers increasingly rely on standardized, high-precision static mixing solutions to improve output quality while reducing operational complexity.

Understanding the MS Static Mixer

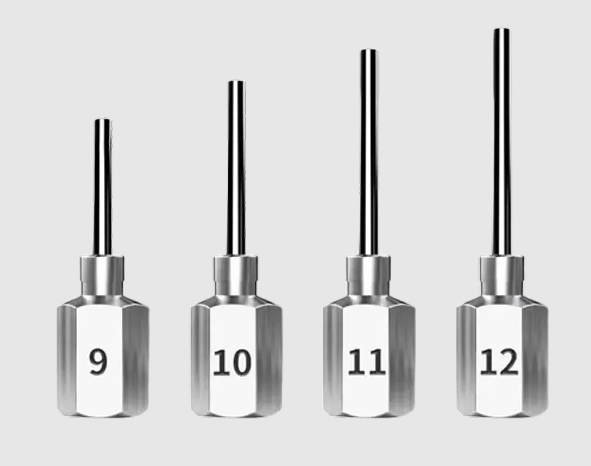

The MS Static Mixer is designed with a yellow round mouth mixing tube that adheres to industry-unified standards. This design not only ensures compatibility with various glue machines but also optimizes the mixing process for a wide range of materials. The static mixer operates on the principle of fluid dynamics, utilizing a series of internal elements to create turbulence and promote thorough mixing without the need for moving parts. This results in a consistent and homogeneous mixture, which is crucial for applications requiring precise formulations.

Key Features of the MS Static Mixer

Standardized Design: The yellow round mouth mixing tube is a hallmark of the MS Static Mixer, ensuring that it meets the stringent requirements of industrial applications. This standardization simplifies integration into existing systems and guarantees reliability.

Versatility: Customers can select from various models of the MS Static Mixer based on the specific mixing characteristics of the two components involved. This adaptability allows manufacturers to tailor their mixing solutions to meet unique production needs.

Enhanced Mixing Efficiency: The design of the MS Static Mixer promotes optimal mixing efficiency, reducing the time and energy required to achieve a uniform blend. This efficiency translates to improved production rates and lower operational costs.

Durability and Reliability: Constructed from high-quality materials, the MS Static Mixer is built to withstand the rigors of industrial environments. Its robust design ensures longevity, minimizing the need for frequent replacements and maintenance.

Applications in Industry

The MS Static Mixer is predominantly used in glue machines, where precise mixing of adhesives is essential. However, its applications extend beyond adhesives to various industries, including:

Chemical Manufacturing: The MS Static Mixer is ideal for mixing chemicals in processes such as polymerization, where consistent mixing is critical for product quality.

Food and Beverage: In the food industry, the mixer can be used for blending ingredients, ensuring uniformity in flavor and texture.

Pharmaceuticals: The pharmaceutical industry benefits from the MS Static Mixer’s ability to create homogeneous mixtures of active ingredients, which is vital for drug formulation.

Improving Production with MS Static Mixers

Implementing the MS Static Mixer in production lines can lead to significant improvements in efficiency and product quality. By providing a reliable and effective mixing solution, manufacturers can reduce waste, enhance product consistency, and ultimately increase profitability. The ability to customize the mixer based on specific requirements further empowers businesses to optimize their processes.

Conclusion

In conclusion, the MS Static Mixer from Contriu represents a significant advancement in mixing technology for industrial applications. Its standardized design, versatility, and efficiency make it an invaluable asset for manufacturers seeking to improve their production processes. By investing in high-quality mixing solutions like the MS Static Mixer, companies can ensure they remain competitive in an ever-evolving market.

For more information on how the MS Static Mixer can benefit your production line, visit Contriu’s website or contact our sales team for personalized assistance.