How M5 Female Needle Improve Automated Soldering Systems

As automation levels rise, manufacturers increasingly rely on automatic soldering machines to ensure consistency, speed, and quality. At the core of these systems is the tin feeding needle, responsible for the precise positioning and controlled delivery of tin wire. Selecting a reliable M5 female needle manufacturer in China is therefore not just a sourcing decision, but a strategic choice impacting production stability and yield rates.

With deep experience in precision components, Contriu has become a trusted supplier of M5 female needles for global automation and electronics manufacturers.

1. Understanding the Function of the M5 Female Tin Feeding Needle

The tin feeding needle is primarily used in automatic soldering equipment, where it guides and positions tin wire with high accuracy during soldering operations.

Its key functions include:

Accurate alignment of tin wire to soldering points

Stable and repeatable tin feeding

Minimisation of solder waste and defects

Support for high-speed, continuous production

In automated soldering environments, even minimal deviations in needle alignment or material quality can lead to poor solder joints, rework, or equipment downtime.

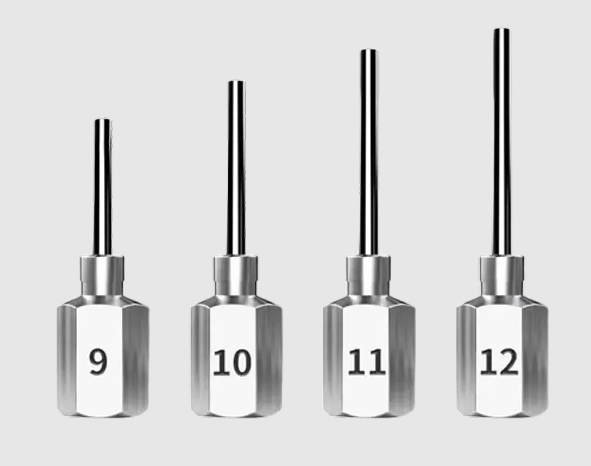

2. Technical Specifications That Define Performance

Professional buyers evaluate M5 female needles based on precise technical parameters rather than appearance alone.

Thread Design

Thread type: M5 internal thread

Structure: Hexagonal design

This configuration ensures secure installation, easy replacement, and compatibility with a wide range of automatic soldering machines.

Needle Tube Material

Material: Stainless steel

Stainless steel provides excellent wear resistance, corrosion resistance, and thermal stability—essential for continuous soldering operations.

Needle Holder Material

Standard options:

Brass (copper color)

Nickel-plated brass

Custom option:

Stainless steel needle holder

The choice of holder material affects durability, conductivity, and long-term performance. Contriu supports material customization to meet specific application requirements.

3. Why Material Selection Is Critical in Tin Feeding Needles

Material quality directly impacts both precision and service life.

Stainless steel needle tubes offer:

High resistance to deformation

Smooth internal surfaces for stable tin wire feeding

Long lifespan under thermal cycling

Brass and nickel-plated holders provide:

Good machinability

Stable mechanical support

Cost-effective performance for high-volume production

For environments requiring enhanced corrosion resistance or higher mechanical strength, Contriu offers fully stainless steel configurations, ensuring performance consistency across demanding conditions.

4. Application Industries and Use Scenarios

M5 female tin feeding needles are widely used across multiple industries where soldering accuracy is essential.

Primary application sectors include:

Consumer electronics and home appliances

Toys and electronic accessories

Communication equipment

Medical devices and instruments

Industrial control systems

In addition, these needles are also used in the U.S. sewing agent industry, where precision dispensing and controlled feeding play a similar functional role.

The versatility of the M5 female needle makes it an indispensable component in automated production lines worldwide.

5. The Role of Precision Manufacturing

Producing a high-quality M5 female needle requires more than basic machining. Critical manufacturing considerations include:

Tight tolerance control on internal threading

Smooth needle tube finishing

Precise concentricity between tube and holder

Stable assembly to prevent vibration or misalignment

As an experienced M5 female needle manufacturer in China, Contriu integrates CNC machining, precision inspection, and controlled assembly processes to ensure product consistency across large-volume orders.

6. Why Global Buyers Source M5 Female Needles from China

China remains a global manufacturing hub for precision components due to its combination of:

Advanced machining infrastructure

Skilled technical workforce

Scalable production capacity

Competitive cost structures

However, not all suppliers meet international quality expectations. Professional buyers look for manufacturers with proven experience, stable quality control systems, and application-level understanding.

Contriu focuses on long-term cooperation with electronic product manufacturers, delivering reliable supply and technical consistency rather than one-time transactions.

7. Customisation and OEM Support

Modern production lines often require non-standard solutions. A capable supplier must support customization without compromising quality.

Contriu offers:

Custom needle holder materials

OEM and drawing-based production

Batch flexibility for different production scales

Stable specifications for long-term repeat orders

This capability is particularly valuable for manufacturers operating multiple soldering platforms or exporting products to different markets.

8. Quality Control and Supply Stability

In automated soldering systems, component failure can halt entire production lines. This makes quality assurance essential.

Professional M5 female needle suppliers implement:

Incoming material inspection

Dimensional verification

Assembly consistency checks

Batch traceability

Through disciplined quality control, Contriu ensures that each M5 female needle performs reliably in real-world production environments.

Conclusion: Precision That Supports Automation

The M5 female tin feeding needle may be a small component, but its impact on soldering accuracy, production efficiency, and product quality is substantial. Choosing a qualified M5 female needle manufacturer in China is critical for manufacturers seeking stable automation performance.

By combining material expertise, precision manufacturing, and industry application knowledge, Contriu delivers M5 female needle solutions trusted by electronic product manufacturers across multiple sectors.