Home > News > Industry News > Choosing the Right Microporous Grouting Needle for Your Injection Project

Choosing the Right Microporous Grouting Needle for Your Injection Project

In the field of structural repair, waterproofing, and soil stabilization, precision and control are critical to achieving long-lasting results. The success of a grouting project often depends on the tools used—especially the Microporous Grouting Needle, which plays a vital role in ensuring even material distribution and effective sealing. Selecting the right type of needle can make the difference between a strong, durable repair and a costly rework.

As a trusted manufacturer and supplier, Contriu specializes in high-performance Microporous Grouting Needles designed to meet the rigorous demands of civil engineering, construction, and maintenance projects.

1. What Is a Microporous Grouting Needle

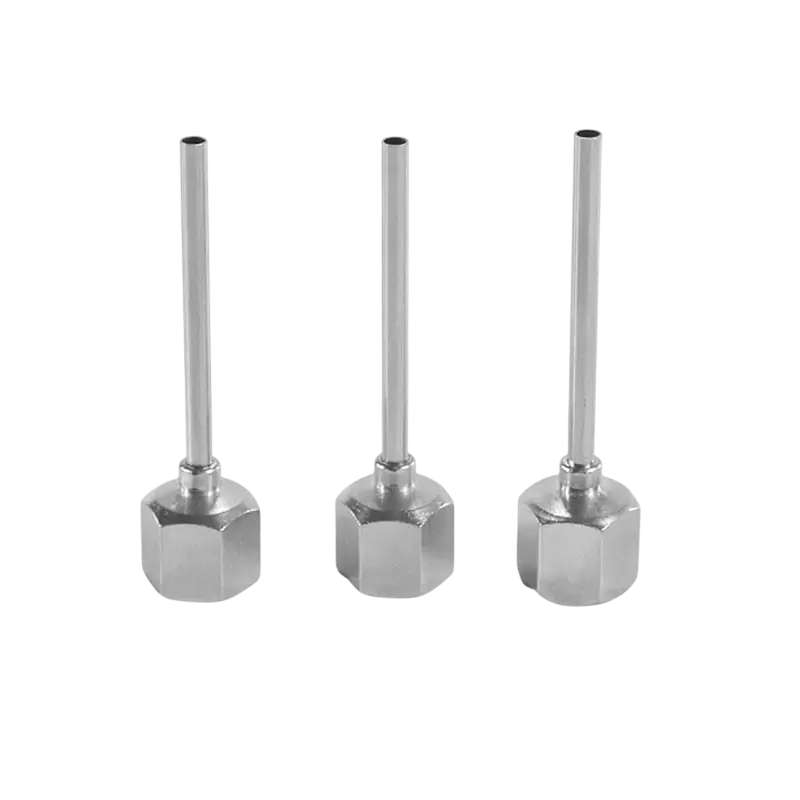

A Microporous Grouting Needle is a precision injection device designed to deliver chemical or cement-based grouting materials into cracks, voids, and pores within concrete or soil structures. Unlike traditional solid or single-hole needles, microporous types feature multiple fine openings that allow for uniform distribution of grout under controlled pressure.

This unique structure helps prevent localized overpressure and ensures that the grout penetrates deeply into fine cracks, micro-voids, and capillaries—creating a dense and watertight seal.

At Contriu, each microporous needle is engineered with precision-drilled pores and durable metal construction to withstand high injection pressures while maintaining smooth, consistent flow performance.

2. Why Microporous Grouting Needles Are Essential

The use of Microporous Grouting Needles has become standard practice in modern injection and waterproofing systems due to their superior performance in achieving uniform grouting. Here are the main reasons why they are preferred by professionals:

Uniform Distribution: The microporous design allows for consistent grout flow, reducing the risk of voids or weak spots.

Reduced Backflow: The even pressure minimizes rebound and backflow, ensuring that more material remains in the targeted area.

Enhanced Penetration: Fine pores enable deep infiltration into microcracks, improving sealing efficiency.

Material Compatibility: Suitable for a wide range of injection materials, including epoxy resin, polyurethane (PU), and cement-based grouts.

Durability: Built from corrosion-resistant stainless steel or high-strength alloys for repeated use in demanding field conditions.

These advantages make Microporous Grouting Needles the tool of choice for concrete crack repair, tunnel waterproofing, dam rehabilitation, and underground infrastructure protection.

3. Key Factors to Consider When Choosing a Microporous Grouting Needle

Selecting the right Microporous Grouting Needle depends on several technical and project-specific factors. Choosing the right combination ensures optimal injection results and project efficiency.

a. Material Compatibility

The type of grout being used—epoxy, PU, or cement slurry—determines the required needle design.

For epoxy or PU resins, use fine-pore stainless steel needles that resist clogging and maintain pressure.

For cementitious materials, select needles with larger pores to handle higher viscosity flow.

b. Pressure Requirements

Different projects demand different injection pressures. High-pressure systems require robust needles with precision sealing to prevent leakage, while low-pressure operations can use lighter models.

c. Needle Length and Diameter

The length and diameter of the needle should match the crack depth and injection area. Longer needles are suitable for deep cracks or soil stabilization, whereas shorter ones are ideal for shallow surface repairs.

d. Pore Size and Distribution

The micropore pattern determines how evenly the material is spread. For highly porous concrete or soil, smaller and denser pores offer better diffusion. Contriu offers customizable pore sizes to fit varying injection materials and project needs.

e. Reusability and Maintenance

For large-scale operations, using reusable Microporous Grouting Needles can reduce costs. Contriu designs its needles for easy cleaning and long-term use without performance degradation.

4. Applications of Microporous Grouting Needles

Microporous Grouting Needles are widely used across various engineering and repair fields, including:

Concrete Crack Injection: Sealing microcracks in bridges, tunnels, and foundations.

Waterproofing Systems: Injecting polyurethane or epoxy grouts to stop leaks in basements and retaining walls.

Soil Stabilization: Improving ground stability in weak soil zones by injecting cementitious materials.

Dam and Reservoir Maintenance: Preventing water seepage through cracks and porous zones.

Infrastructure Rehabilitation: Reinforcing aging concrete structures to restore integrity and durability.

In each of these cases, the even grout distribution achieved by microporous needles significantly enhances the sealing effect and prolongs the service life of the repaired structure.

5. Why Choose Contriu as Your Microporous Grouting Needle Supplier

As a professional manufacturer and exporter, Contriu has built a reputation for providing durable, precision-engineered Microporous Grouting Needles that meet international standards. The company focuses on combining innovation, material excellence, and advanced manufacturing technology to deliver products that consistently perform in demanding environments.

Key advantages of choosing Contriu include:

High-Quality Manufacturing: Produced using precision machining and quality-controlled metal materials.

Customizable Solutions: Tailored designs available for different pore sizes, lengths, and injection systems.

Strong Export Capability: Efficient global logistics and reliable supply for international clients.

Technical Support: Expert guidance to help clients choose the right tools for their specific grouting applications.

With years of experience in injection tools and waterproofing systems, Contriu continues to serve global construction professionals with dependable, high-performance solutions.

6. Conclusion

Selecting the right Microporous Grouting Needle is essential for achieving superior injection efficiency, deeper penetration, and long-term structural durability. By understanding your project requirements—material type, pressure level, and injection depth—you can choose the most suitable needle design to ensure consistent and reliable results.

With its commitment to quality and precision, Contriu stands out as a trusted partner in providing professional Microporous Grouting Needles for construction, waterproofing, and repair industries worldwide. Whether you’re working on a small-scale concrete crack repair or a large infrastructure rehabilitation project, Contriu delivers the tools you need to achieve excellence in grouting performance.