Home > News > Industry News > Top Reasons Industrial Glue Needles Use 304 Stainless Steel & What That Means for Durability

Top Reasons Industrial Glue Needles Use 304 Stainless Steel & What That Means for Durability

Introduction

When it comes to adhesive application, the performance of industrial glue dispensing equipment depends on precision, reliability, and durability. Among the many factors that affect performance, the choice of needle material is one of the most critical. Manufacturers across industries—from electronics and medical devices to automotive and consumer goods—consistently rely on 304 stainless steel for glue needle tubes. But why is this specific material the go-to standard?

In this article, we’ll explore the top reasons industrial glue needles use 304 stainless steel, what advantages it brings in terms of durability, and why Contriu Technology has become a trusted provider of high-performance stainless steel dispensing needles.

Why Material Choice Matters in Glue Needles

Dispensing adhesives may seem simple, but the process demands extraordinary precision. A high-performance dispensing needle must:

Deliver glue in controlled, repeatable amounts.

Resist corrosion from chemically aggressive adhesives.

Withstand pressure without bending or deforming.

Maintain smooth inner walls to allow even flow.

If the wrong material is chosen, issues like clogging, inconsistent flow, premature wear, and contamination can disrupt operations. For these reasons, manufacturers rely on 304 stainless steel, a material that balances mechanical strength, corrosion resistance, and cost-effectiveness.

Key Features of Contriu Technology’s Stainless Steel Dispensing Needles

Contriu Technology designs and manufactures stainless steel blunt-tip dispensing needles with the following construction:

Brass Nickel-Plated Needle Holder – Provides strong mechanical support and corrosion resistance. Nickel plating prevents wear and maintains a secure grip for long-term use.

304 Stainless Steel Needle Tube – High rigidity and excellent chemical resistance make this the core material choice.

Bayonet Base – Ensures a solid, leak-proof connection with dispensing systems, reducing downtime.

Precision Machining Without Burrs – Guarantees smooth adhesive flow and protects delicate substrates during dispensing.

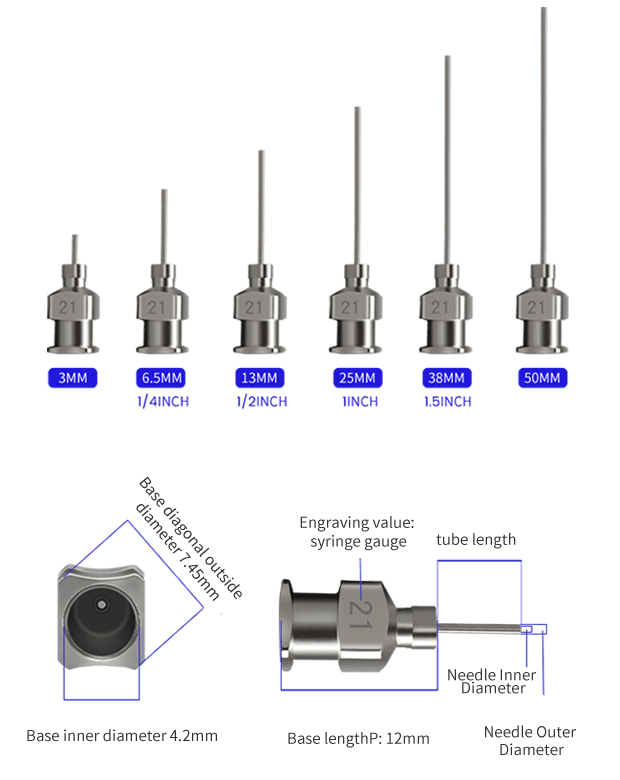

Standard Sizes & Customization – Available in 1/4 inch (6.5 mm), 1/2 inch (13 mm), 1 inch (25 mm), and 1.5 inch (38 mm), with options for custom lengths to meet unique industry needs.

Top Reasons Industrial Glue Needles Use 304 Stainless Steel

1. Exceptional Corrosion Resistance

Adhesives often contain solvents, curing agents, or reactive compounds that can degrade metals over time. 304 stainless steel resists corrosion even when exposed to harsh chemicals like epoxies, cyanoacrylates, and UV-cured adhesives. This makes it suitable for industries that demand both longevity and safety.

2. High Rigidity and Mechanical Strength

Glue needles must maintain dimensional stability under pressure. 304 stainless steel offers high rigidity, preventing deformation even under repeated use. Unlike softer materials, it maintains its internal diameter, ensuring consistent glue flow.

3. Burr-Free Precision Machining

304 stainless steel allows for precision machining, which produces smooth, burr-free inner walls. This reduces the risk of adhesive buildup, prevents clogging, and ensures accurate glue placement every time.

4. Extended Service Life

Durability translates to lower replacement frequency. Industrial production lines operate continuously, and downtime is costly. Using stainless steel needles reduces maintenance interruptions, making them a cost-effective choice in the long run.

5. Safe for Sensitive Applications

Blunt-tip stainless steel needles protect delicate surfaces from scratches or punctures, which is critical in electronics, optics, and medical device assembly. The material’s smooth finish enhances safety and reliability.

6. Compatibility with Multi-Industry Applications

From microelectronics solder masking to medical syringe adhesive application, 304 stainless steel performs consistently across industries. Its versatility reduces the need for multiple material types, simplifying procurement and supply chain management.

The Durability Advantage of 304 Stainless Steel

Durability is not just about lifespan—it’s about maintaining performance over time. A needle that bends, corrodes, or clogs will not only fail prematurely but also compromise product quality.

Consistency Over Time – The hardness of 304 stainless steel ensures that the needle retains its original dimensions.

Resistance to Wear – Continuous dispensing of adhesives can create friction. Stainless steel resists abrasion, maintaining smooth flow channels.

Reduced Contamination Risk – Unlike plastics that may degrade or shed particles, stainless steel remains stable and inert.

This combination of features makes 304 stainless steel the most cost-efficient and technically reliable material for industrial dispensing applications.

Industries That Rely on Stainless Steel Glue Needles

Electronics Manufacturing

Adhesive dispensing is critical for bonding chips, securing wires, and applying conformal coatings. Stainless steel needles ensure precise application without damaging fragile circuits.

Medical Devices

Needles must meet strict safety and cleanliness requirements. 304 stainless steel resists contamination, ensuring biocompatibility in medical device assembly.

Automotive and Aerospace

Vehicles and aircraft require adhesives for vibration damping, structural bonding, and sealing. Durability and chemical resistance make stainless steel needles ideal for high-demand environments.

Laboratory and Research

In scientific applications, controlled adhesive dispensing is vital for experimental accuracy. Stainless steel’s stability ensures reproducibility in test results.

Stainless Steel vs. Alternative Materials

| Feature | 304 Stainless Steel | Plastic Needles | Aluminum Needles |

|---|---|---|---|

| Durability | Long lifespan, wear-resistant | Easily damaged, disposable | Moderate durability |

| Corrosion Resistance | Excellent | Poor | Good, but prone to oxidation |

| Precision | Burr-free machining, smooth flow | Limited | Moderate |

| Cost Efficiency | High initial cost, lower long-term expense | Low upfront cost, high replacement rate | Moderate |

| Applications | Industrial, medical, electronics | Disposable uses | General but limited in aggressive environments |

This comparison highlights why 304 stainless steel remains the industry leader.

Best Practices for Using Stainless Steel Dispensing Needles

Match Gauge to Adhesive Viscosity – Thicker adhesives require larger gauge needles to maintain smooth flow.

Select Proper Length – Use shorter lengths for pinpoint precision and longer ones for reaching confined areas.

Clean After Each Use – Prevent adhesive buildup by flushing needles with approved solvents.

Monitor for Wear – While durable, needles should still be inspected periodically to ensure optimal performance.

Use Secure Connections – Contriu’s bayonet base ensures leak-free operation—always lock firmly into place.

Why Contriu Technology Leads in Stainless Steel Dispensing Solutions

Contriu Technology has earned recognition as a reliable supplier by offering:

ISO-certified production for consistent quality.

Full customization to meet unique client needs.

Advanced machining processes ensuring burr-free precision.

Strong after-sales technical support for global clients.

Their expertise ensures that every stainless steel dispensing needle delivers the accuracy, durability, and versatility required by modern manufacturing.

Conclusion

The choice of 304 stainless steel for industrial glue needles is not coincidental—it’s a result of decades of proven performance in durability, precision, and safety. By resisting corrosion, maintaining rigidity, and ensuring smooth dispensing, stainless steel blunt-tip needles allow industries to achieve reliable adhesive application across a wide spectrum of uses.

With manufacturers like Contriu Technology leading the way in design and production, businesses can trust that their dispensing systems are built to last, delivering both quality and cost efficiency in today’s demanding markets.