Home > News > Industry News > Multi-Point Dispensing Made Easy: Inside Contriu’s Multi-Tube Metal Needles

Multi-Point Dispensing Made Easy: Inside Contriu’s Multi-Tube Metal Needles

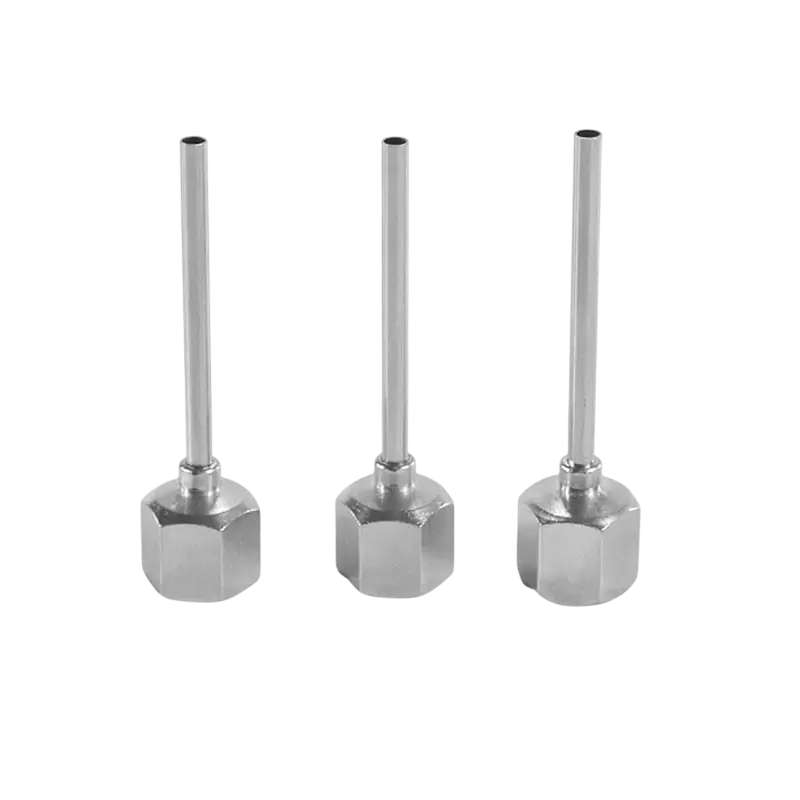

In the fast-paced world of precision manufacturing, efficiency, accuracy, and durability are vital. Every second counts, and every drop of adhesive or sealant must be applied with utmost precision. This is exactly where Contriu’s Multi-Tube Metal Needles stand out. Engineered for high-speed, high-precision automation equipment, these all-stainless-steel multi-tube needles represent a breakthrough in multi-point dispensing technology.

By combining advanced material engineering, precise polishing, and superior corrosion resistance, Contriu’s Multi-Tube Metal Needles are designed to meet the demanding requirements of modern production environments — delivering consistent performance, reduced cycle times, and long-term reliability.

Superior Design for Precision Manufacturing

Contriu’s Multi-Tube Metal Needles are built with precision manufacturing techniques that ensure exceptional performance under the most demanding conditions. Each needle is made entirely from high-quality stainless steel, providing strong corrosion resistance, high strength, and excellent durability.

The internal and external surfaces of every needle are precision-polished to achieve an ultra-smooth finish, ensuring a consistent and stable flow of adhesive or other dispensing materials. This smooth interior not only prevents clogging but also maintains stable fluid output even at high speeds — critical for automated production lines.

The multi-tube design allows for simultaneous multi-point glue dispensing, which significantly shortens the production cycle and enhances productivity. Whether used for bonding, sealing, coating, or filling, these needles ensure even distribution of materials across multiple application points.

Engineered for High-Speed Automation

Modern production systems demand tools that can keep up with high-speed automation while maintaining pinpoint accuracy. Contriu’s Multi-Tube Metal Needles are optimized for this purpose. Their heavy load resistance allows them to operate under continuous high-pressure and high-speed conditions without deformation or performance loss.

This makes them ideal for high-precision automation equipment, where timing, accuracy, and reliability are key. From electronics assembly to automotive manufacturing and medical device production, Contriu’s multi-tube needles integrate seamlessly into existing dispensing systems, helping manufacturers reduce downtime and maximize throughput.

Multi-Point Simultaneous Dispensing Efficiency

Traditional single-point dispensing methods often struggle to meet the speed and precision demands of modern production. Contriu’s Multi-Tube Metal Needles solve this by enabling multiple dispensing points to operate at the same time.

This multi-point simultaneous dispensing not only saves valuable processing time but also ensures a consistent and uniform application of adhesives or other fluids. The result is improved product quality and a more efficient workflow — a perfect balance between precision and productivity.

In industries where timing and uniformity are essential, such as PCB assembly, optical bonding, and precision coating, Contriu’s multi-tube technology delivers measurable advantages that translate directly into production gains.

Corrosion and Load Resistance for Long-Term Stability

Durability is at the core of Contriu’s Multi-Tube Metal Needles. The stainless steel construction provides outstanding resistance to corrosion and mechanical stress, making them suitable for use with a wide variety of adhesives, sealants, and industrial fluids — even those with strong chemical properties.

Their heavy load resistance ensures long-lasting stability even in continuous, high-pressure production environments. Manufacturers can rely on these needles to maintain consistent dispensing performance over extended use, reducing the need for frequent replacements or maintenance downtime.

Polished Perfection for Smooth Dispensing

The inner and outer surfaces of Contriu’s Multi-Tube Metal Needles are meticulously precision-polished, minimizing friction and optimizing fluid flow. This ensures that materials move through the needle smoothly and evenly, with minimal residue buildup.

The polishing process enhances both dispensing precision and needle longevity, helping maintain consistent results even after prolonged use. This makes Contriu’s needles not only efficient but also cost-effective over time.

Why Choose Contriu

With years of expertise in precision fluid dispensing technology, Contriu has established itself as a trusted manufacturer dedicated to quality, innovation, and reliability. Every Multi-Tube Metal Needle is the result of rigorous research, strict manufacturing standards, and advanced polishing technology.

By focusing on durability, precision, and customer-specific needs, Contriu continues to provide the manufacturing industry with tools that enhance automation efficiency and maintain superior product quality. The company’s ongoing commitment to excellence ensures that its products remain at the forefront of dispensing technology worldwide.

Conclusion

In a world where manufacturing demands are constantly evolving, Contriu’s Multi-Tube Metal Needles deliver the perfect blend of precision, durability, and performance. Their corrosion-resistant stainless-steel design, high load-bearing capacity, and precision-polished surfaces make them ideal for high-speed, high-precision automation systems.

By enabling multi-point simultaneous dispensing, these needles help manufacturers reduce production cycles, improve product consistency, and achieve greater operational efficiency. As a leader in dispensing technology, Contriu continues to set new standards for quality and innovation in the industry.

For more product details, please visit:

Contriu’s Multi-Tube Metal Needles – Shenzhen Contriu Technology Co., Ltd.