Home > News > Industry News > Precision Redefined: How Contriu’s Customized Bayonet Precision Needles Drive Accuracy and Efficiency in Modern Applications

Precision Redefined: How Contriu’s Customized Bayonet Precision Needles Drive Accuracy and Efficiency in Modern Applications

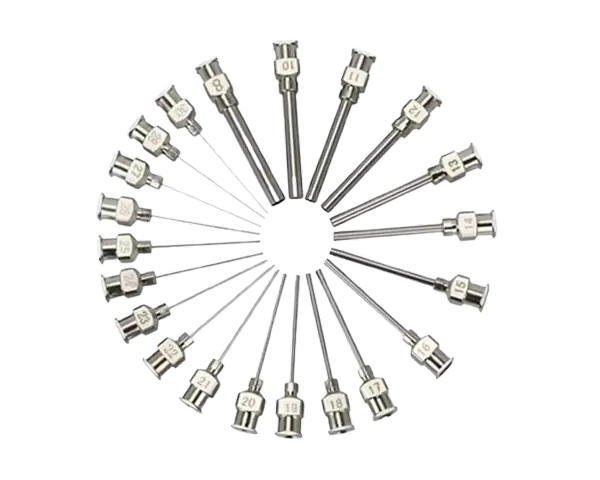

In industries where microscopic accuracy defines performance, the demand for high-precision components has never been greater. From medical diagnostics to analytical instrumentation and microfluidics, every micron counts. One of the most critical components enabling these applications is the customized bayonet precision needle — a product engineered not only for dimensional accuracy but also for repeatability, safety, and reliability under exacting operational conditions.

At the forefront of this technological excellence is Contriu, a company dedicated to delivering advanced precision-engineered solutions. Through innovation, material science, and rigorous quality control, Contriu has redefined what it means to manufacture customized bayonet precision needles that meet the highest standards of global industries.

Understanding the Functionality of Bayonet Precision Needles

A bayonet precision needle is distinguished by its bayonet locking mechanism, a secure and efficient connection interface that ensures rapid attachment and detachment between components such as syringes, nozzles, or fluidic systems. Unlike traditional threaded connections, bayonet systems provide:

Quick engagement/disengagement with a simple twist-lock motion.

Stable and leak-proof sealing for high-pressure or sterile environments.

Enhanced mechanical strength to prevent accidental detachment.

These design attributes make bayonet precision needles ideal for applications requiring repeatable, sterile, and vibration-resistant connections. They are extensively used in fields such as medical devices, laboratory automation, biotechnology, pharmaceutical filling systems, and industrial precision dispensing.

The Advantage of Customization

Off-the-shelf components often fail to meet the nuanced requirements of advanced equipment and specialized processes. Customized bayonet precision needles allow for fine-tuning in dimensions, materials, coatings, and connection tolerances to match the exact performance needs of the system they integrate with.

Contriu specializes in providing tailored needle solutions, offering customization in several critical aspects:

Material Selection – From surgical-grade stainless steel to titanium alloys and polymer composites, Contriu engineers select the ideal material based on corrosion resistance, chemical compatibility, and mechanical strength.

Needle Geometry – Precision control over inner/outer diameter, tapering, bevel angle, and tip design allows for optimal flow control, injection accuracy, and penetration performance.

Surface Treatment and Coating – Advanced polishing, passivation, and coating techniques such as PTFE, Parylene, or DLC improve lubricity, biocompatibility, and wear resistance.

Bayonet Interface Tolerances – Customized locking grooves and alignment structures guarantee stable and reproducible connections under dynamic mechanical stresses.

This level of precision engineering ensures that every Contriu customized bayonet precision needle is fit-for-purpose, enhancing operational efficiency, extending service life, and reducing maintenance or downtime.

Applications Across Industries

The adaptability and reliability of Contriu’s customized bayonet precision needles make them indispensable across multiple high-value sectors:

Medical and Pharmaceutical: Used in injection systems, diagnostic devices, drug delivery units, and sample extraction instruments where sterility and dimensional accuracy are vital.

Laboratory Automation: Integral to fluidic systems, pipetting robots, and reagent dispensers for precise volume control and repeatable performance.

Industrial Dispensing Systems: Applied in adhesive deposition, inkjet printing, and electronic assembly processes requiring exact fluid delivery.

Biotechnology and Analytical Equipment: Essential for cell culture sampling, chromatography systems, and microfluidic devices requiring chemically resistant, precision-tuned needles.

Each industry presents unique operational challenges — from chemical exposure to pressure fluctuation — and Contriu’s customized design capabilities ensure that each needle performs flawlessly in its intended environment.

Innovation Through Collaboration

Contriu’s product development philosophy emphasizes collaboration with clients. Its engineering teams work directly with R&D departments and OEM partners to design prototypes, conduct feasibility studies, and optimize product geometries for mass production.

By leveraging simulation modeling, rapid prototyping, and performance testing, Contriu ensures that customized bayonet precision needles achieve superior performance before final integration. This partnership-driven approach minimizes development risks and accelerates time-to-market for new devices and systems.

Conclusion

In today’s high-precision world, even the smallest components make a monumental difference. The customized bayonet precision needle stands as a testament to engineering sophistication — where design, material science, and manufacturing precision converge to achieve performance excellence.

With a proven legacy of innovation and reliability, Contriu continues to lead the industry by delivering customized solutions that empower accuracy, enhance efficiency, and drive progress across multiple disciplines.

Whether in a laboratory, a surgical suite, or an advanced manufacturing line, Contriu’s customized bayonet precision needles redefine what true precision means.