Home > News > Industry News > Precision at the Micron Level: How Stainless Steel Needles Redefine Industrial Dispensing Accuracy

Precision at the Micron Level: How Stainless Steel Needles Redefine Industrial Dispensing Accuracy

In modern manufacturing environments, precision is not a competitive advantage—it is a baseline requirement. From electronics assembly and medical device production to automotive components and advanced materials processing, stainless steel needles play a critical role in ensuring accurate, repeatable, and contamination-free dispensing.

Unlike generic dispensing accessories, professional-grade stainless steel dispensing needles are engineered as precision components, where material selection, machining accuracy, and structural stability directly affect production yield and process consistency. Manufacturers such as Contriu have focused on optimizing these variables to meet the demanding requirements of multi-industry precision dispensing applications.

Understanding Stainless Steel Dispensing Needles

A stainless steel needle is a precision fluid delivery component designed to dispense controlled volumes of liquids, pastes, or adhesives with high positional accuracy. Its performance is defined by three core factors:

Structural rigidity

Internal surface finish

Connection stability with dispensing systems

High-quality stainless steel needles are not interchangeable commodities; they are engineered tools tailored to specific process tolerances.

Structural Design: Engineering for Stability and Accuracy

Nickel-Plated Brass Needle Holder

The needle holder serves as the mechanical interface between the dispensing system and the needle tube. In high-end stainless steel dispensing needles, a brass needle holder with nickel plating is commonly used.

Key advantages include:

Excellent corrosion resistance in chemical environments

Improved wear resistance during repeated installation

Stable dimensional accuracy under continuous operation

This design ensures a long service life even in high-frequency dispensing cycles.

304 Stainless Steel Needle Tube: Rigidity and Reliability

The needle tube is the most critical functional component. 304 stainless steel is widely adopted due to its balanced mechanical and chemical properties.

Technical benefits:

High rigidity to prevent bending or deformation

Strong resistance to corrosion and oxidation

Stable performance across a wide temperature range

Contriu utilizes precision-formed 304 stainless steel needle tubes to maintain consistent internal diameters, ensuring predictable flow behavior during dispensing.

Bayonet Base: Secure and Solid Connection

A bayonet base design provides a firm mechanical lock between the needle and dispensing equipment. Compared to threaded or friction-fit designs, bayonet connections offer:

Faster installation and removal

Reduced risk of loosening during operation

Improved repeatability in automated systems

This structural feature is especially valuable in automated production lines where downtime and misalignment must be minimized.

Precision Machining: Burr-Free for Controlled Flow

Importance of Burr-Free Processing

In precision dispensing, even microscopic burrs can disrupt flow consistency, introduce turbulence, or cause material accumulation at the needle tip.

High-quality stainless steel needles are manufactured using:

Precision CNC machining

Internal surface polishing

Strict dimensional inspection

Contriu emphasizes burr-free internal and external finishes, ensuring smooth material flow and protecting sensitive components in downstream processes.

Smooth and Accurate Dispensing Performance

Precision machining directly translates into:

Stable dispensing pressure

Reduced dripping or stringing

Clean cutoff at the needle tip

These characteristics are essential for industries requiring micron-level accuracy.

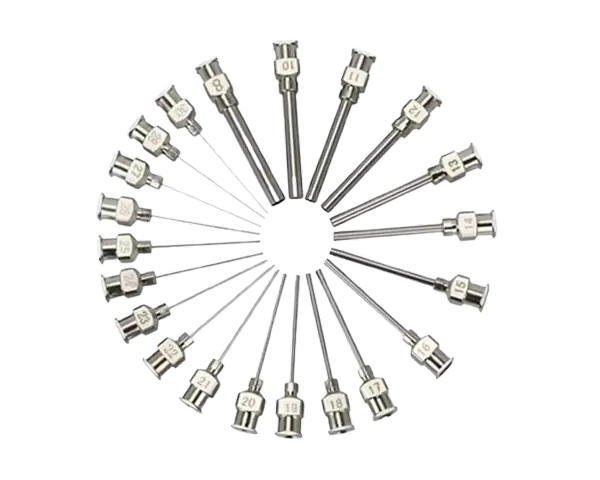

Standard Specifications and Customization Capability

Conventional Length Options

Professional stainless steel dispensing needles are commonly available in standardized lengths to meet diverse application needs:

1/4 inch (6.5 mm)

1/2 inch (13 mm)

1 inch (25 mm)

1.5 inch (38 mm)

These lengths cover the majority of industrial dispensing scenarios.

Support for Any Length Customization

Beyond standard specifications, advanced manufacturers support full-length customization. Customization enables precise alignment with specific fixtures, workpiece geometries, or automated dispensing heads.

Customization options typically include:

Non-standard lengths

Special internal diameters

Tailored connection interfaces

Contriu’s customization capability allows manufacturers to optimize dispensing efficiency without modifying existing production equipment.

Multi-Industry Applications of Stainless Steel Needles

Electronics and Semiconductor Manufacturing

In electronics assembly, stainless steel needles are used for:

Solder paste application

Conductive adhesive dispensing

Encapsulation of sensitive components

High rigidity and burr-free finishes protect delicate substrates and ensure uniform deposition.

Medical and Life Sciences

In regulated environments, stainless steel needles support:

Diagnostic reagent dispensing

Medical device assembly

Laboratory automation

Material stability and corrosion resistance are critical to maintaining process integrity.

Automotive and Industrial Manufacturing

Applications include:

Sealant and lubricant dispensing

Adhesive bonding of components

Precision coating processes

Stainless steel needles must withstand harsh chemicals and continuous operation without performance degradation.

Emerging Advanced Manufacturing Fields

As additive manufacturing, battery technology, and microfluidics evolve, demand for high-precision stainless steel dispensing needles continues to grow.

Conclusion: Precision Components for Precision Industries

Stainless steel needles are foundational components in modern precision dispensing systems. Their performance depends on material selection, structural design, machining accuracy, and connection stability.

By combining nickel-plated brass holders, rigid 304 stainless steel needle tubes, bayonet base connections, and burr-free precision machining, Contriu provides stainless steel dispensing needles that support smooth, accurate, and repeatable dispensing across multiple industries.

For manufacturers pursuing higher accuracy and process reliability, investing in professionally engineered stainless steel needles is a strategic decision—not a consumable expense.