Home > News > Industry News > High-Quality Customized PP Needle Manufacturer in China | Precision and Durability Guaranteed

High-Quality Customized PP Needle Manufacturer in China | Precision and Durability Guaranteed

In the competitive world of precision manufacturing, every component used in the production process plays a vital role in ensuring quality, efficiency, and reliability. From adhesive dispensing to assembly line operations, even the smallest part can significantly influence performance outcomes. One such essential yet often underestimated tool is the PP (polypropylene) needle — particularly when it comes to the accurate and damage-free application of adhesives.

Among the global leaders in this field, Contriu stands out as a premier customized PP needle manufacturer in China, offering innovative designs that combine flexibility, precision, and durability. The company’s one-piece PP needle solution has been engineered to meet the demanding requirements of modern industries, especially those involving anaerobic glue applications, where precision and care are paramount.

1. The Concept of the One-Piece Needle Design

At the heart of Contriu’s product innovation is its one-piece needle structure, designed to make direct contact with workpieces without causing any surface damage. Unlike metal or rigid plastic needles that can easily scratch or deform delicate materials, the one-piece PP needle provides a gentle yet reliable interface between the adhesive and the substrate.

This design is particularly advantageous in precision manufacturing sectors such as electronics, automotive components, optical devices, and medical equipment, where maintaining product integrity is non-negotiable. The flexible and elastic needle tube absorbs application pressure, ensuring smooth adhesive flow while preventing mechanical stress on the workpiece. The result is a dramatic reduction in the defective rate of finished products and improved consistency in adhesive dispensing.

2. Why Polypropylene (PP) Is the Material of Choice

The success of Contriu’s customized PP needles begins with material selection. Polypropylene (PP) offers an exceptional balance of mechanical strength, flexibility, and chemical resistance. It is non-reactive, ensuring that it does not interfere with the chemical properties of anaerobic glues or other specialty adhesives.

Unlike metal needles, which may cause unwanted chemical reactions or corrosion over time, PP maintains stability under prolonged exposure to adhesive materials. Additionally, its smooth surface allows for consistent and uninterrupted adhesive flow, minimizing the risk of clogging or turbulence.

This makes PP needles not only cost-effective but also highly reliable for repetitive and high-precision applications, making them an indispensable tool for manufacturers seeking consistent performance in adhesive systems.

3. The Value of Customization

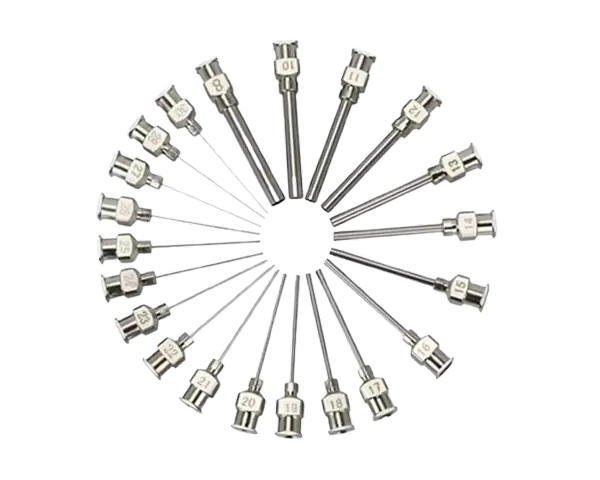

No two production processes are identical, which is why Contriu emphasizes the importance of customized PP needle solutions. Each customer can specify parameters such as needle length, diameter, flexibility, and tip design to match their equipment and application needs.

This high degree of customization ensures optimal results for every type of adhesive — from low-viscosity sealants to high-viscosity anaerobic compounds. Contriu’s engineering team uses advanced precision molding technologies to achieve tight tolerances and uniformity, guaranteeing that each needle performs exactly as intended.

Customization not only enhances process efficiency but also reduces material waste and machine downtime, leading to measurable savings over time. Contriu’s focus on application-specific design sets it apart from generic manufacturers, allowing clients to achieve unmatched precision and reliability in adhesive dispensing.

4. Perfect for Anaerobic Glue Applications

Anaerobic adhesives require precise, controlled, and contamination-free dispensing because they cure in the absence of oxygen. This makes the material of the dispensing needle especially critical. The wrong material can trigger premature curing or lead to uneven application.

Contriu’s customized PP needles are engineered specifically for such scenarios. The one-piece structure maintains stable pressure and ensures consistent adhesive distribution, while the PP material’s non-reactive properties prevent any interference with the curing process.

By eliminating scratching or pressure damage, the needle also maintains the quality and structural integrity of the workpiece — a key factor in high-end manufacturing environments where product aesthetics and functional performance must remain flawless.

5. Contriu’s Commitment to Quality and Innovation

As a trusted PP needle manufacturer in China, Contriu has built its reputation on three pillars: innovation, precision, and dependability. Every production batch undergoes rigorous testing to ensure that each needle meets international standards for dimensional accuracy, chemical resistance, and performance consistency.

The company’s investment in state-of-the-art molding equipment and automated inspection systems ensures stable quality, even in large-scale production runs. Furthermore, Contriu’s experienced engineering team continuously refines its designs based on customer feedback and market trends, staying ahead of evolving industry requirements.

Contriu’s philosophy is simple: to deliver components that help manufacturers achieve higher productivity and lower defect rates while maintaining cost efficiency and operational reliability.

6. Eco-Friendly and Safe Manufacturing

In addition to product performance, Contriu also prioritizes sustainability and safety. The PP materials used are environmentally friendly, recyclable. Production processes are optimized to minimize waste and energy consumption, aligning with global trends toward eco-conscious manufacturing.

This commitment to sustainability ensures that customers not only receive high-quality products but also contribute to a greener and safer production ecosystem.

7. Why Global Manufacturers Choose Contriu

With years of expertise and a strong foundation in materials science and process engineering, Contriu has become a trusted global supplier for clients seeking reliable customized PP needles. The company’s combination of competitive pricing, fast delivery, and technical support makes it a preferred partner for OEMs and industrial producers worldwide.

Contriu’s core advantages include:

Custom-tailored designs to meet specific application requirements.

Damage-free adhesive dispensing with flexible, elastic needle construction.

Precision molding and inspection for consistent performance.

Expert guidance and technical support for specialized adhesive applications.

Stable global supply chain and rapid response to client needs.

When it comes to customized PP needle solutions in China, Contriu delivers not just a product — but a promise of quality, innovation, and performance excellence.

Conclusion

In precision manufacturing, the smallest components often make the biggest difference. The customized PP needle from China, developed by Contriu, exemplifies this truth. With its one-piece, flexible design that prevents surface damage and ensures accurate adhesive application, it has become an essential tool for manufacturers using anaerobic glue and other advanced adhesive materials.

Through its dedication to customization, material excellence, and sustainable manufacturing, Contriu continues to lead the industry — providing PP needle solutions that redefine precision, durability, and efficiency.