Home > News > Industry News > Custom Lengths & Sizes: When & Why You Might Need a Non-Standard Glue Needle

Custom Lengths & Sizes: When & Why You Might Need a Non-Standard Glue Needle

In industries where adhesives and sealants are used daily—from electronics assembly to medical device manufacturing—precision dispensing is everything. The size, shape, and material of your dispensing needle can significantly impact performance, efficiency, and even safety. While standard stainless steel glue needles cover most applications, there are times when custom lengths and sizes are not just convenient but absolutely necessary.

This article explores the reasons behind choosing non-standard glue needles, how to identify when they’re required, and what industries benefit the most. We’ll also cover maintenance tips, ordering considerations, and expert advice on making the right selection.

Why Standard Isn’t Always Enough

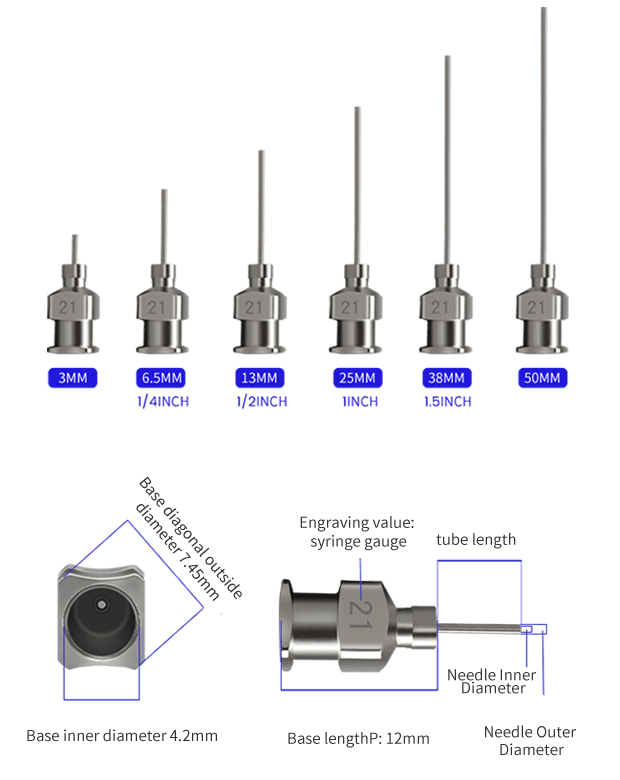

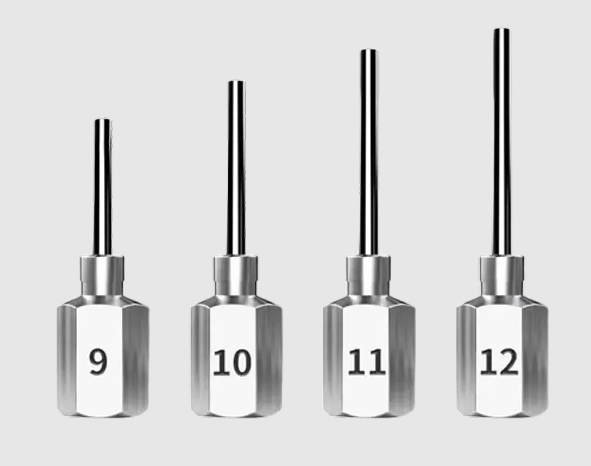

Standard glue needles are designed to meet general industry needs. They come in common lengths and gauges, suitable for dispensing a wide range of adhesives. However, every industry—and often every project—presents unique challenges.

For example:

A microelectronics manufacturer may need ultra-fine needles for placing adhesive dots smaller than a millimeter.

A furniture manufacturer applying wood adhesives may need extra-long needles to reach deep joints.

A lab working with highly viscous resins may require wide-bore custom needles to ensure smooth flow.

When these specialized needs arise, custom non-standard glue needles provide the solution. See available stainless steel glue needle options here

When You Might Need a Custom Glue Needle

1. Handling High-Viscosity Adhesives

Thicker adhesives like epoxy, silicone, or polyurethane often clog standard fine-gauge needles. A custom wide-gauge needle ensures smooth, consistent flow without clogging or pressure buildup.

2. Reaching Difficult or Confined Spaces

Sometimes components are located deep inside an assembly. Extended-length glue needles can reach these areas without requiring disassembly, saving time and reducing risk of damage.

3. Micro-Dispensing for Precision Work

On the opposite end, extra-fine custom needles allow precise adhesive placement in applications like semiconductor packaging, microfluidics, or medical device assembly.

4. Unique Dispensing Angles

Certain projects may require adhesive to be dispensed at unusual angles. Custom bent or tapered glue needles make it possible to apply adhesives without repositioning parts.

5. Preventing Cross-Contamination

Custom-color-coded or labeled needles help differentiate adhesive types, ensuring accurate application and preventing costly errors in labs and production lines.

Industries That Benefit from Custom Needles

Electronics

From circuit boards to microchips, electronics assembly often requires glue dots smaller than a grain of sand. Custom ultra-fine stainless steel needles help achieve these tolerances.

Medical Devices

Devices such as catheters, surgical tools, and diagnostic kits require precision bonding under strict hygienic standards. Custom-length needles ensure adhesives are delivered exactly where needed.

Automotive & Aerospace

In these industries, adhesives seal and bond critical components under high-performance conditions. Extended or bent needles allow adhesives to reach tight crevices in engines or fuselage assemblies.

Laboratory R&D

Research labs deal with a variety of adhesives, from resins to biological adhesives. Tailored needle sizes reduce waste and enhance experimental accuracy.

Advantages of Custom-Length & Non-Standard Needles

Greater Accuracy – Needles tailored to the exact job ensure clean lines and consistent volume.

Reduced Downtime – Prevent clogging and rework by using the right needle size from the start.

Improved Safety – Proper needle length reduces risks of backflow, spillage, and accidental exposure.

Cost Efficiency – Though custom needles may have higher upfront costs, they reduce material waste and production errors.

Considerations Before Ordering Custom Glue Needles

Material Compatibility

Most custom glue needles are made from stainless steel for strength and chemical resistance, but ensure the material suits your adhesive.Gauge Selection

Match the inner diameter to your adhesive’s viscosity. For example, low-viscosity adhesives require fine gauges, while thicker materials need wider ones.Length Requirements

Balance reach with stability. Extremely long needles may bend or flex, so reinforcement may be needed.System Compatibility

Verify that the custom needle fits your syringe, dispenser, or automated machine.Supplier Expertise

Always choose suppliers with proven experience in manufacturing precision dispensing equipment. Explore Contriu’s stainless steel glue needle solutions as a starting point.

Maintenance Best Practices for Custom Glue Needles

Even custom needles require regular care:

Clean Immediately After Use – Prevent adhesive buildup using compatible solvents.

Inspect Regularly – Look for tip deformation, corrosion, or clogs.

Label Clearly – Avoid mixing up needles across projects.

Store Properly – Keep in dry, sealed containers to maintain sterility and prevent dust accumulation.

For labs, ultrasonic cleaners can be used for thorough cleaning without damaging delicate fine-gauge needles.

Common Challenges & How to Overcome Them

Challenge 1: Needle Bending

Longer needles are more prone to bending. Solution: use reinforced shafts or shorter needles with flexible tubing extensions.

Challenge 2: Clogging in Fine Needles

Micro-dispensing often leads to blockages. Solution: pre-warm adhesives or use tapered designs for smoother flow.

Challenge 3: Increased Costs

Custom needles can be more expensive. Solution: order in bulk and evaluate ROI against reduced waste and downtime.

External Insights & Resources

If you’re evaluating whether custom needles are the right investment, these resources may help:

Adhesives.or– Information on adhesive applications and dispensing innovations.

Techspray Dispensing Guide– Practical guidance on electronics adhesive dispensing tools.

Conclusion

In fast-paced, high-precision industries, one-size-fits-all doesn’t always work. Custom glue needles—whether longer, shorter, wider, or finer—address specific challenges that standard options cannot. They help ensure accuracy, reduce downtime, and improve overall efficiency.

By understanding when and why you might need a non-standard glue needle, and by partnering with trusted suppliers, you can optimize your adhesive dispensing process. For durable, customizable solutions, check out Contriu stainless steel glue needles