Why Syringe Connector Design Matters More Than You Think

In modern medical practice, attention is often focused on advanced devices and complex systems. Yet some of the most critical risks and efficiencies in healthcare lie in components that appear deceptively simple. The syringe connector is one such component. Acting as the physical and functional interface between syringes, tubing, catheters, and medical equipment, syringe connectors play a decisive role in fluid accuracy, patient safety, and system compatibility.

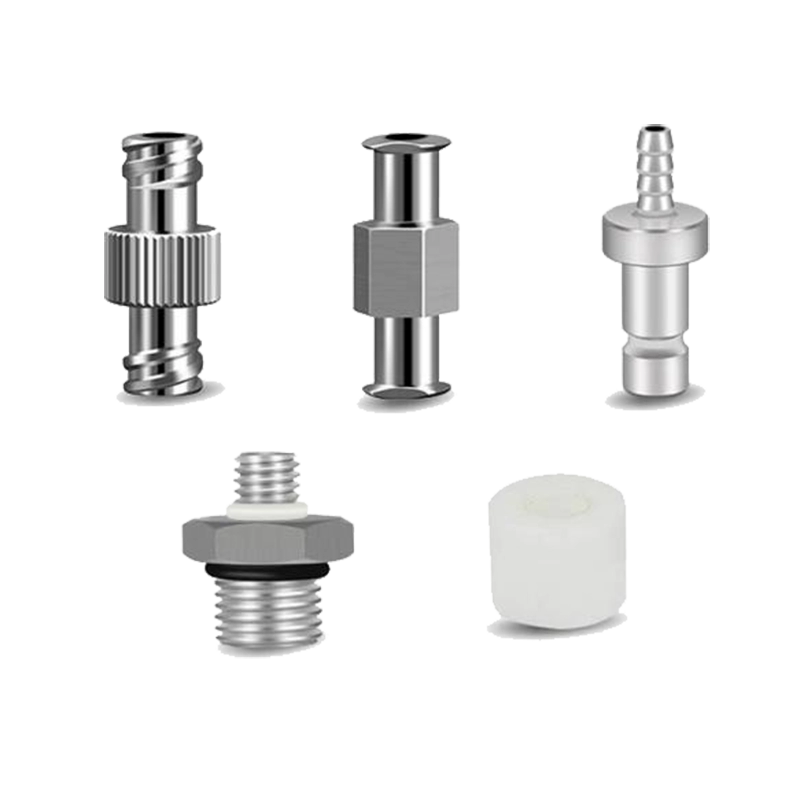

Understanding the Function of a Syringe Connector

At its core, a syringe connector ensures secure, leak-free, and correctly aligned fluid transfer between a syringe and a secondary device. However, in clinical environments where multiple therapies coexist—such as anesthesia, infusion, enteral feeding, and contrast delivery—the connector’s role expands significantly.

A well-designed syringe connector must simultaneously deliver:

Mechanical stability under pressure

Chemical compatibility with diverse fluids

Accurate alignment to prevent misconnections

Ease of use for clinicians under time pressure

Failures at this interface can lead to dosing errors, leaks, contamination, or even life-threatening misconnections.

Connector Standards and Clinical Safety

Luer and ISO-Compliant Interfaces

Historically, the Luer connector has been the most common interface in syringe-based systems. However, its universal design also introduced risk, particularly cross-connection between incompatible medical applications.

Modern syringe connectors increasingly comply with ISO 80369 standards, which define application-specific connectors to reduce misconnections across:

Enteral feeding

Neuraxial applications

Respiratory systems

Limb cuff inflation

Adherence to these standards is no longer optional for manufacturers supplying regulated healthcare markets.

Contriu develops syringe connectors with strict dimensional control to support ISO-compliant integration and reduce clinical misuse risks.

Material Selection: More Than Plastic Choice

Polymer Performance and Biocompatibility

Material choice directly affects connector safety and durability. Commonly used materials include:

Medical-grade polypropylene (PP)

Polycarbonate (PC)

ABS or specialized blends

Each material must be evaluated for:

Biocompatibility (ISO 10993)

Resistance to stress cracking

Transparency or opacity requirements

Sterilization compatibility (EO, gamma, steam)

Inadequate material selection can result in micro-cracking, leakage, or chemical interaction with drugs.

Manufacturing Precision and Tolerance Control

Why Microns Matter

Syringe connectors rely on tight dimensional tolerances to ensure proper engagement without excessive force. Deviations as small as a few microns can affect:

Sealing integrity

Locking strength

Ease of connection and disconnection

Precision injection molding, controlled tooling wear, and in-process inspection are essential to maintaining connector consistency at scale.

Contriu applies controlled production workflows to ensure repeatable connector geometry across high-volume manufacturing runs.

Leakage Prevention and Pressure Performance

Mechanical Design Considerations

Depending on the application, syringe connectors may be exposed to:

High injection pressures

Pulsatile flow

Repeated connection cycles

Design features such as sealing angles, thread depth, and surface finish directly influence performance. Proper validation includes:

Pressure burst testing

Leak testing under dynamic conditions

Cycle fatigue testing

A connector that performs well in static tests may still fail under real clinical use if not engineered holistically.

Usability and Human Factors Engineering

Reducing Clinical Error Through Design

In fast-paced healthcare environments, connectors must support intuitive use. Human factors considerations include:

Tactile feedback during connection

Audible or visual confirmation of proper engagement

Ergonomic grip surfaces

Poor usability increases the likelihood of incomplete connections or accidental dislodgement.

By integrating human factors principles early in development, Contriu supports connectors that align with real-world clinical workflows.

Syringe Connectors in Specialized Applications

Syringe connectors are widely used in:

Drug delivery systems

Contrast media injection

Anesthesia and pain management

Diagnostic sampling

Disposable medical kits

Each application imposes unique requirements for sterility, pressure, and compatibility, reinforcing the need for application-specific connector design rather than generic solutions.

Conclusion

Though small in size, the syringe connector plays an outsized role in ensuring safe, accurate, and efficient medical care. From material science and precision manufacturing to regulatory compliance and usability, every design decision directly affects clinical outcomes.

By combining engineering rigor, quality control, and application awareness, Contriu delivers syringe connector solutions designed to meet modern healthcare demands with confidence and consistency.