Customizing Multi-Tube Metal Needles: Design Options & Use Cases

In modern industrial and medical applications, the demand for precision and efficiency has driven the development of advanced needle systems. Among these, multi-tube metal needles have emerged as a versatile and high-performance solution. They are widely used in sectors ranging from laboratory automation and chemical processing to medical devices and industrial manufacturing.

At Contriu, we specialize in producing high-quality multi-tube metal needles that offer customizable design options, exceptional durability, and superior performance, meeting the unique needs of diverse industries.

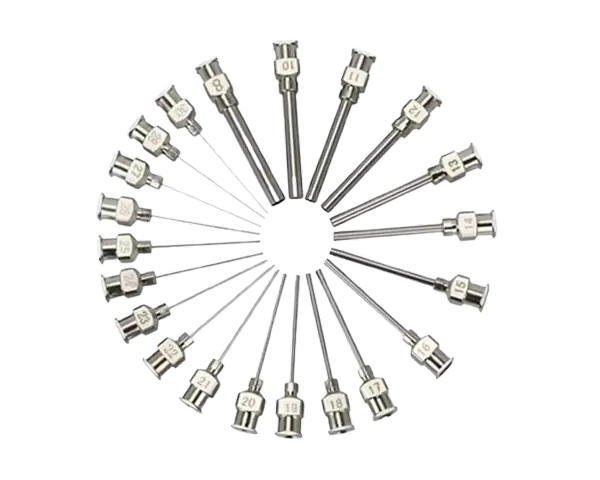

1. What Are Multi-Tube Metal Needles

Multi-tube metal needles are assemblies composed of several fine tubes integrated into a single needle structure. Each tube can serve a specific function, such as fluid delivery, sampling, or simultaneous multi-channel operations. Compared to single-channel needles, multi-tube designs offer enhanced efficiency, precision, and versatility.

Contriu leverages advanced metal fabrication techniques to produce multi-tube needles with tight tolerances, corrosion resistance, and consistent flow characteristics, ensuring reliable performance in even the most demanding applications.

2. Design Options and Customization

Customization is a key advantage of multi-tube metal needles. Contriu offers a wide range of design options to tailor the needles to specific applications:

a. Tube Configuration:

Needles can feature different numbers of tubes—ranging from 2 to 12 or more—arranged in parallel or concentric patterns to optimize flow and functionality.

b. Material Selection:

Materials include stainless steel, titanium, and specialty alloys, chosen based on chemical compatibility, mechanical strength, and sterilization requirements.

c. Tube Diameter and Wall Thickness:

Precise control over tube diameter and wall thickness allows users to regulate fluid flow rates and minimize pressure loss.

d. Tip Design:

Tips can be beveled, blunt, or rounded, depending on whether the application requires penetration, dispersion, or gentle fluid contact.

e. Surface Treatment:

Options such as electropolishing, coating, or passivation enhance chemical resistance, reduce friction, and prevent contamination.

With these options, Contriu ensures that every multi-tube metal needle is optimized for its intended function, offering unparalleled precision and reliability.

3. Applications Across Industries

a. Laboratory and Analytical Instruments:

Multi-tube metal needles are widely used in automated liquid handling systems, chromatography, and mass spectrometry. Multiple channels allow simultaneous sampling or injection, improving throughput and accuracy.

b. Medical Devices:

In medical applications, these needles enable multi-site injections, fluid collection, and advanced diagnostic procedures. Customizable tip designs and biocompatible materials ensure patient safety and comfort.

c. Industrial Manufacturing:

They are also employed in chemical processing, lubrication systems, and high-precision dispensing. The ability to control multiple flows in parallel reduces processing time and enhances production consistency.

d. Research and Development:

Multi-tube needles are invaluable for R&D applications, including microfluidics, tissue engineering, and controlled chemical reactions, where precise delivery and distribution are critical.

4. Advantages of Choosing Multi-Tube Metal Needles

a. Enhanced Efficiency:

Simultaneous multi-channel delivery reduces operation time and improves workflow.

b. Precision and Accuracy:

Customizable tube configurations and diameters allow precise control over fluid flow rates.

c. Durability and Longevity:

High-quality metals and protective treatments ensure long-lasting performance, even in corrosive or high-pressure environments.

d. Flexibility:

Design options allow multi-tube needles to be adapted for specific applications, whether in research, manufacturing, or medical use.

e. Safety and Reliability:

Optimized designs minimize leakage, contamination, and operational errors, enhancing both user and product safety.

Contriu combines all these advantages in each multi-tube metal needle, providing solutions that meet rigorous industrial and regulatory standards.

5. Tips for Selecting the Right Multi-Tube Metal Needle

Assess the Application Requirements: Consider flow rates, chemical compatibility, and operational pressure.

Determine the Tube Count and Arrangement: Choose the configuration that optimizes efficiency and space utilization.

Material Considerations: Select metals based on corrosion resistance, sterilization needs, and mechanical strength.

Tip and Surface Design: Ensure the tip type and surface finish align with the intended function.

Quality Assurance: Choose suppliers like Contriu who provide precision manufacturing, rigorous testing, and consistency across production batches.

By following these guidelines, users can maximize performance and longevity while minimizing operational risks.

Conclusion

Multi-tube metal needles represent a sophisticated solution for high-precision fluid delivery and sampling in a variety of industrial, medical, and research applications. Their versatility, efficiency, and reliability make them indispensable in modern technological environments.

With Contriu’s expertise in design, customization, and high-quality manufacturing, organizations can access tailored solutions that meet exacting standards, ensuring performance, safety, and durability. From laboratory automation to advanced medical procedures, multi-tube metal needles from Contriu are engineered to deliver precision where it matters most.