Home > News > Industry News > Precision in Your Hands: How the AB Glue Gun Redefines Two-Component Adhesive Dispensing

Precision in Your Hands: How the AB Glue Gun Redefines Two-Component Adhesive Dispensing

In manufacturing, repair, and assembly operations, the performance of an adhesive is only as reliable as the tool used to dispense it. Two-component adhesives—commonly referred to as AB glue—are widely used for their superior bonding strength, chemical resistance, and durability. However, inaccurate mixing ratios, inconsistent output, or cumbersome equipment can significantly reduce efficiency and increase material waste.

This is where the AB Glue Gun becomes a critical productivity tool. Designed for precise control, portability, and ease of operation, modern manual AB glue guns support accurate mixing ratios while improving workflow efficiency.

1. Understanding the AB Glue Gun and Its Role

An AB glue gun is a dispensing tool specifically designed for two-component adhesives, such as epoxy, polyurethane, and acrylic systems. These adhesives require precise proportioning of resin (A) and hardener (B) to achieve optimal bonding performance.

Unlike single-component adhesive applicators, AB glue guns must ensure:

Accurate mixing ratios

Uniform material flow

Controlled dispensing volume

Minimal material waste

The right AB glue gun directly influences adhesive performance, curing consistency, and production quality.

2. Portable 50ML Manual AR Glue Gun: Compact but Capable

2.1 Lightweight and Portable Design

The portable 50ML manual AR glue gun is engineered for flexibility across diverse working environments. Its light, compact construction allows operators to work efficiently without fatigue, even during extended use.

Key benefits of the lightweight design include:

Easy handling in confined or mobile workspaces

Reduced operator strain

Faster setup and repositioning

For on-site repairs, small-batch assembly, or precision bonding tasks, portability is a decisive advantage.

2.2 Simple Structure, Easy Operation

Manual operation ensures straightforward use without reliance on electrical or pneumatic systems. This simplicity reduces training requirements and maintenance complexity while increasing reliability.

Contriu designs its AB glue guns with a user-centric approach, emphasizing intuitive operation and consistent performance.

3. Flexible Mixing Ratios for Multiple Adhesive Systems

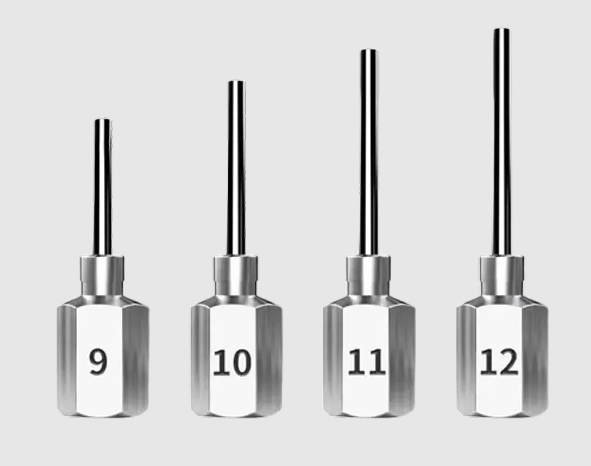

3.1 Supporting 1:1, 2:1, and 10:1 Ratios

One of the most important features of a professional AB glue gun is its ability to accommodate different mixing ratios, such as 1:1, 2:1, and 10:1. These ratios correspond to a wide range of industrial adhesive formulations.

By supporting multiple ratios, the same AB glue gun can be used across different applications, including:

Structural bonding

Electronic component encapsulation

Automotive and industrial repairs

This flexibility significantly reduces tooling costs and improves equipment utilization.

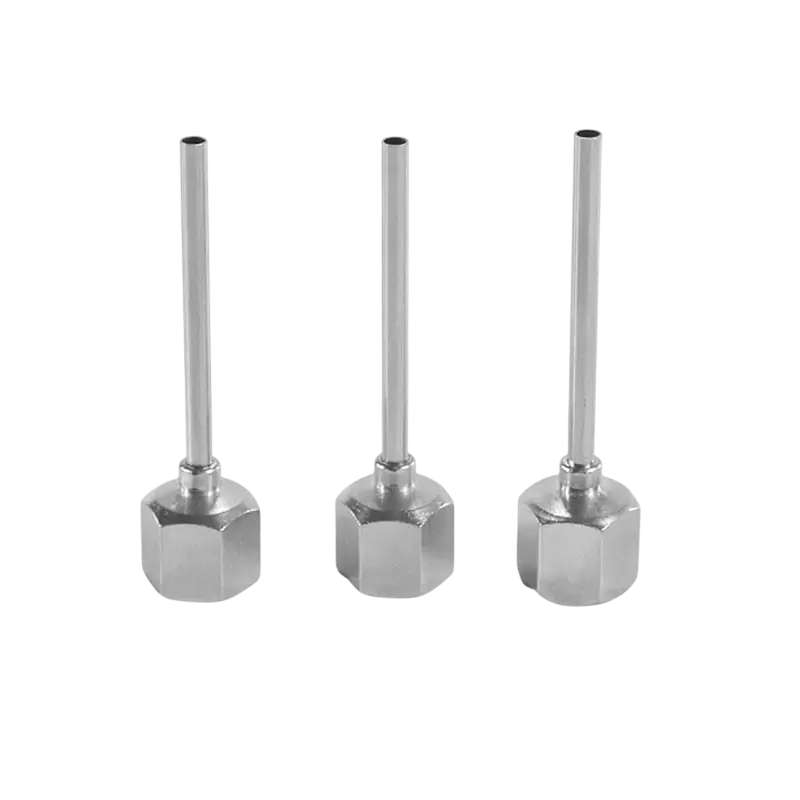

3.2 Compatibility with Two-Component 50ML Dazzle Barrels

The AB glue gun is designed to work seamlessly with two-component 50ML dazzle barrels, ensuring stable material delivery and accurate proportioning. This compatibility allows operators to switch materials quickly without compromising precision.

4. Precise Control of Adhesive Output

4.1 Free Control of Dispensing Volume

Accurate control over adhesive output is essential for minimizing waste and ensuring consistent bond quality. The manual AB glue gun allows operators to freely control the amount of adhesive dispensed, making it suitable for both small precision tasks and larger bonding areas.

This controlled dispensing helps:

Prevent over-application

Reduce cleanup time

Improve bonding consistency

4.2 Improving Production Efficiency

By delivering adhesive exactly where and how much it is needed, AB glue guns help streamline production processes. Faster application and reduced rework directly translate into improved throughput.

Contriu’s AB glue gun designs focus on balancing precision and speed, ensuring that efficiency gains do not come at the expense of quality.

5. Cost Savings Through Smarter Dispensing

5.1 Reduced Material Waste

Two-component adhesives can be expensive, especially in specialized industrial formulations. Inaccurate mixing or uncontrolled dispensing leads to unnecessary waste.

Using a properly designed AB glue gun helps:

Maintain correct mixing ratios

Avoid premature curing

Optimize adhesive usage per application

5.2 Lower Equipment and Maintenance Costs

Manual AB glue guns require no external power sources, resulting in:

Lower initial investment

Minimal maintenance

Long service life

This makes them a cost-effective solution for both small workshops and large-scale production environments.

6. Application Scenarios Across Industries

AB glue guns are widely used across multiple sectors, including:

Electronics and electrical assembly

Automotive repair and component bonding

Industrial manufacturing and maintenance

Construction and structural reinforcement

DIY and professional repair services

The versatility of portable 50ML manual AB glue guns allows them to adapt to both precision and general bonding tasks.

Conclusion: The AB Glue Gun as a Productivity Enabler

The AB glue gun is more than a simple dispensing tool—it is a critical interface between advanced adhesive chemistry and real-world application. A portable 50ML manual AR glue gun offers the ideal balance of flexibility, precision, and cost efficiency.

By supporting multiple mixing ratios, enabling precise control of adhesive output, and reducing waste, AB glue guns help improve production efficiency while lowering operational costs. With thoughtfully engineered solutions from Contriu, businesses can rely on dependable adhesive dispensing that supports both quality and productivity.