Home > News > Industry News > Stainless Steel Advantage: Engineering Better US Style Metal Cylinders

Stainless Steel Advantage: Engineering Better US Style Metal Cylinders

The US Style Metal Cylinder has evolved into a core component across manufacturing, mechanical engineering, energy equipment, pneumatic systems, automotive structures, and multiple high-demand industrial sectors. As design standards continue to tighten and application environments grow increasingly severe, the industry has shifted toward high-performance cylinders capable of delivering dimensional stability, corrosion resistance, and extended service life.

Manufacturers such as Contriu have been at the forefront of this shift, refining material selection, machining tolerances, thermal resistance characteristics, and structural reinforcement to ensure US style metal cylinders meet both legacy specifications and modern performance expectations.

1. Material Science Foundations: Why Stainless Steel Outperforms Traditional Alloys

A US Style Metal Cylinder fabricated from high-grade stainless steel offers substantial technical advantages over carbon steel, cast alloy, or aluminum tubes. In industrial environments involving pressure cycling, thermal fluctuation, and corrosive agents, stainless steel maintains structural reliability.

1.1 Superior Corrosion Resistance

The chromium-rich composition of stainless steel forms a self-repairing passive oxide layer that prevents pitting, chemical degradation, and atmospheric corrosion.

This is especially critical in:

oil and gas processing

marine and offshore projects

chemical and pharmaceutical systems

steam, high-humidity, or acidic environments

Contriu’s cylinders use material grades optimized for both corrosion resistance and mechanical strength, ensuring stable long-term performance even under aggressive operating conditions.

1.2 High Temperature Resistance and Dimensional Stability

Thermal shock and sustained high temperatures often cause distortion, micro-cracking, or strength reduction in inferior alloys. Stainless steel cylinders retain their geometry, load capacity, and sealing fit during:

prolonged high-temperature exposure

rapid thermal cycling

heat-assisted forming or molding processes

Dimensional integrity is essential for maintaining sealing performance, pressure accuracy, and mechanical alignment in critical assemblies.

2. Integrated Manufacturing: Eliminating Weak Points Through Precision Engineering

Modern US Style Metal Cylinders are no longer assembled through multiple welded joints. Instead, leading manufacturers adopt integrated forming and machining processes, which compress structural tolerances and enhance durability.

2.1 Seamless Forming for Structural Strength

A cylinder produced through integrated forming eliminates weld seams and joint interfaces that traditionally serve as stress concentrators. This provides:

higher internal pressure capacity

reduced risk of fatigue failure

superior resilience to vibration and impact

longer service life under cyclic loads

2.2 Precision CNC Machining

Contriu employs CNC-controlled turning, honing, and internal surface polishing processes to achieve:

high circularity precision

micro-level surface smoothness

uniform wall thickness

stable fit with embedded screws and accessory components

These manufacturing enhancements contribute to improved sealing performance, smoother mechanical motion, and compatibility with high-pressure or high-speed applications.

3. Structural Engineering: Embedded Screw Design for Secure Mounting

The US Style Metal Cylinder utilizes a screw-embedded interface, a design element that greatly strengthens mechanical fastening reliability.

3.1 Anti-Loosening Performance

By embedding screws directly into the cylinder wall structure, the system achieves:

stable locking force

reduced risk of loosening during vibration or shock

compatibility with automated or high-load systems

3.2 Easy Installation and Alignment

Embedded screw features simplify integration with brackets, manifolds, and mechanical assemblies, reducing alignment errors and installation time.

3.3 Extended Service Life Through Reinforced Threads

Contriu’s reinforced threaded interfaces maintain their integrity even after repeated assembly cycles, resisting stripping and metal fatigue over long-term operation.

4. Durability and Mechanical Reliability: Why These Cylinders Outlast Traditional Components

Durability is not simply a function of material—it is the result of engineering interactions between manufacturing, surface treatment, mechanical design, and usage environment.

4.1 Resistance to Deformation

The high-strength stainless-steel body resists bending, warping, and compression deformation under:

static loads

dynamic cyclic stresses

impact or shock loads

rapid pressure fluctuations

4.2 Repeated Use Without Performance Loss

US Style Metal Cylinders from Contriu are engineered for repeated use in industrial environments where components undergo:

continuous pressure cycling

mechanical extension and retraction

high operating frequencies

Unlike lower-cost alternatives, these cylinders do not lose structural integrity or sealing capability over time.

4.3 Long Service Life, Reduced Replacement Costs

Customers in manufacturing, automation, and energy industries benefit from significantly reduced maintenance cycles, lower downtime, and improved system reliability.

5. Customization: Adapting to the Modern Industrial Landscape

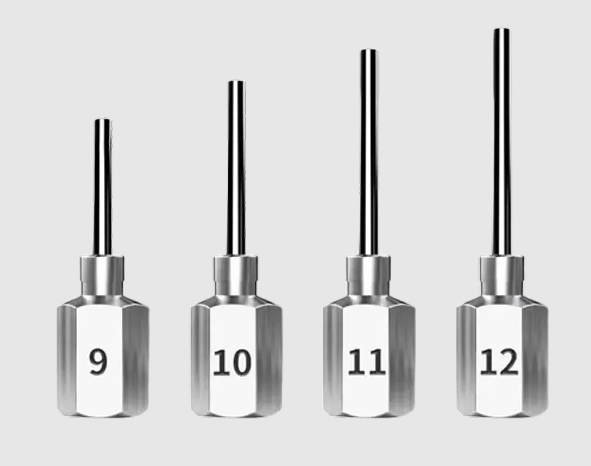

One of the strongest advantages of the US Style Metal Cylinder is its adaptability. Industrial systems no longer rely on one-size-fits-all components; instead, they require cylinders tailored to exacting performance criteria.

5.1 Customizable Dimensions

Contriu supports customizations such as:

inner diameter

outer diameter

wall thickness

length (short tube, extended tube, deep cylinder)

This ensures compatibility across diverse machine architectures.

5.2 Performance-Specific Modifications

Depending on application requirements, cylinders can be optimized for:

high-pressure resistance

elevated temperature tolerance

dynamic mechanical loads

special chemical environments

5.3 Full Model Range for Sector-Specific Applications

Contriu offers custom models suitable for:

pneumatic cylinders

hydraulic systems

industrial automation equipment

laboratory and testing devices

energy and petrochemical installations

This modular flexibility makes the US Style Metal Cylinder a future-proof choice for engineers and purchasing managers.

Conclusion

The modern US Style Metal Cylinder integrates material science, mechanical engineering, and advanced manufacturing to deliver exceptional performance in demanding environments. Its stainless-steel construction, high-temperature resistance, corrosion-proof design, embedded screws, and customizable specifications make it a strategic solution for high-reliability industrial applications.

With manufacturers like Contriu pushing the boundaries of precision production, businesses can rely on these cylinders to deliver long-term operational stability, reduced downtime, and superior mechanical integrity.